A centre pivot is an essential part of many farms worldwide. What a farmer expects from a pivot is efficiency, reliability, and longevity. A farmer wants assurance that his investment will benefit him for decades to come.

One such wise farmer who makes the right choices is James O’Kennedy, who farms on the farm Doornkloof, in the Swellendam district. Longevity is a golden word in his vocabulary, and Reinke is his first choice for irrigation.

James says that his biggest need on the farm was water. “When I started farming here, there was not much. There was no water supply or pipelines from the river. We had to transport water from the river five kilometres away, with tractors and trailers. Over the years, I developed and expanded the farm.

“The first sixteen hectares close to the river were irrigated with a tractor and old-fashioned sprinklers. When I turned the sprinklers on for the first time, I got a lump in my throat, and that is where it all started.

A successful harvest depends on a reliable pivot. Reinke makes every drop of water count.

“Moving the pipes from one section to the other was quite challenging. That is when I started doing research and acquired a self-propelled water cannon. I could not irrigate all my fields with the cannon sprayer, and the irrigator did not handle slopes very well. Then, the next irrigation generation was introduced, and it was pivots.

“At that time, I contacted Spilhaus, and the product that they suggested to me was a Reinke pivot. That is where it all started.”

In 1981, Doornkloof’s first 13-tower pivot was installed close to the river.

James says: “The amazing thing of a pivot compared to the old traditional sprinklers, is the fact that there is no need to pull in the pipes every day. I can leave the pivot to work on its own, it does what it needs to, and it is very reliable.

James O’Kennedy, farmer from Doornkloof in the Swellendam district, is one hundred percent satisfied with his Reinke pivots.

“The secret of a Reinke pivot is its low profile; it has a lightweight structure, and the quality of the material of which the pivot is made of is top-class. A Reinke pivot is also silent – you hardly hear it move through your fields. I’ve had other pivots set up on the farm, but in my opinion and during my 43 years of irrigation, there is no other pivot that can compare with a Reinke,” he adds.

“After the first pivot was set up in 1981, there was no turning back. Later that year, we bought two more 25-hectare Reinke pivots and another 12-tower with an overhang.

“At that time, we had four Reinke pivots, and number five, I call it the orphan, was the replacement for the one 25-hectare pivots that was taken by a very strong north-western wind.

“Despite the fact that the pivot got taken by the strong wind, nothing else was damaged, and this can be attributed to the strength of the steel with which the pivots are designed and manufactured,” says James.

“Over the years, we have expanded and mainly produced cash crops like maize and other grains. At that stage, I was uneducated when it came to summer crops, and I soon realised that I needed expert advice.

“I made a point of visiting the Douglas and Prieska areas every year to see what the grain farmers do and how they do it: how they cultivate, how they irrigate … I did not try to be clever, and through the process I was very fortunate to meet precious people who shared their knowledge with me to bring back to the farm and implemented it here,” says James.

He adds: “And that way I climbed the ladder. I started with seven tonnes of maize per hectare and later achieved harvests of fourteen tonnes per hectare by applying the expertise I learned. In 1994, I started a fairly large sheep farming section on the farm. I grew up in the Karoo with sheep farming, so this mainly is actually where my expertise and knowledge was.”

At that stage, James was the second-largest wool farmer in the Western Cape. He also expanded further and set up a dairy with around 1 000 Jersey cows. “We also started planting perennial crops, including alfalfa, under irrigation to reduce inputs from outside.

“After twenty years of irrigation, I realised another unique characteristic of the high-strength steel of a Reinke pivot is the fact that no matter how thin the steel is, the pivot will not give in. The structure will get a hole in it and spray water, but the construction remains standing.

A bit of rust won’t prevent the work from being done. One of the oldest Reinke pivots on James O’Kennedy’s farm still irrigates non-stop.

“Not all our fields are table-top smooth. Reinke pivots have an advantage over other pivots in that they can handle larger inclines both uphill and downhill. Because the pivot is light, it moves with ease. Whether the pivot is going downhill or climbing, it does not carry a heavy weight. You do not hear the pivot complain either. You just see the pivot moving through the valley and doing what it has to do,” explains James.

He highlights a few characteristics of Reinke’s pivots: “The biggest advantages of Reinke pivots in my eyes are the reliability, assurance, longevity, and minimal wear on the gearboxes. If there are no problems at the pump houses, the pivots will never be standing. As an irrigation farmer, I believe that prevention is better than cure. If you look at your pivot, it will look after you in return.

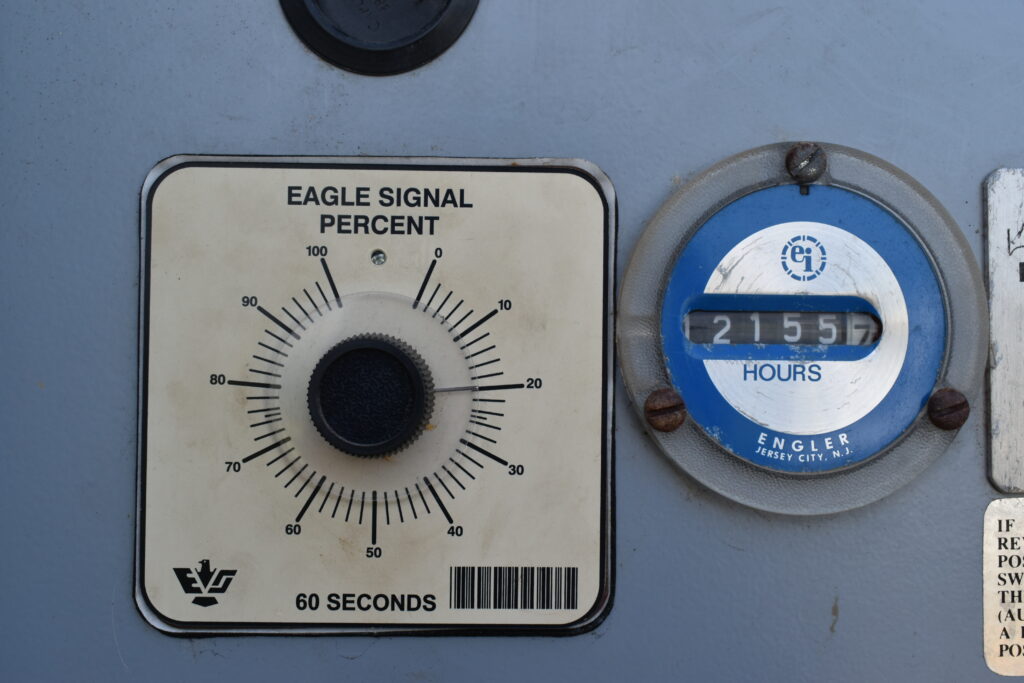

One of the oldest Reinke pivots on Doornkloof boasts with 121 557 hours of faithful service on the clock.

“I will never, until my last breath, buy anything other brand than a Reinke. The service and support I receive from the Reinke team and Patrick Ellis are great,” says James.

After many successful years, James decided to scale down his farming operation. His advice to young farmers and other irrigation farmers out there is that everything in life comes with passion.

Gain the necessary knowledge and do some thorough research about the pivot you are buying as soon and as well as you can; get to know the system. If the owner of the farm does not have experience on his farm with what he is doing, that farm can never stay on its feet.

“I was privileged to grow up, work hard, and gain knowledge about what was going on around me, and for that I am forever grateful.”

If you want a reliable and durable irrigation system on your farm, call Patrick Ellis on +27(0)31-350-4525 or send an e-mail to patrickellis@reinke.com. Also visit Reinke’s website at www.reinke.com for more information.

Read more about how to produce profit on your pastures with Reinke Irrigation.