In industry and trade, the term “raw silk” typically refers to raw mulberry silk. Reeling is a technique for extracting the silk filaments from cocoons to weave them together to create compact, untwisted, and degummed silk thread.

To reel raw silk, you have to find the right end of the cocoon filament and join a few ends together. A reeling machine is used to unwind the silk filament from the cocoon. In all cases the process starts with cooking the cocoons and keeping them in a basin with warm water.

Different reeling machines

Cocoons can be reeled in directly on standard reels or indirectly on small reels. The reeling machines’ water temperatures are optimised for the type of appliance, water, and cocoons. The reeling basin and reeler receive cooked and brushed cocoons with filaments. Clear filaments are tied to a reel bench hook near the reeling basin.

The reels with bright yellow silk threads on the Charka. (Source: jica.go.jp)

Techniques for reeling

There are several ways to reel silk:

1. Traditional charka

The Indian cottage reeling industry uses the charka, a manually operated reeling machine. Charkas are usually installed in backyards or in simple, roofed shelters. Charkas have mud platforms, distributors, and reels. The dimensions are usually 60 x 120 cm with a 90 cm-high mud platform that is rectangular in shape with a basin that covers the builtin fireplace. This basin, which is a 45 to 50 cm oval mud pot or copper vessel, cooks and holds the silk cocoons. The reeler sits on the mud platform, which covers the basin to its brim.

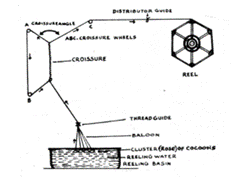

The basin has a metal thread guide (tharpatti) with apertures. It is securely attached to a thin, long stick leaning against the front edge of the mud platform near the basin. Firewood or dry twigs are burned to heat the basin water in the fireplace or oven. Paddy husks and peanut shells are used as fuel in some places, and a chimney vents smoke. A wheel on a vertical axis drives the wooden traverse rod in a distributor. The traverse rod is parallel to the platform’s front and 20 to 25 cm away. The reel’s cord belt drives the wheel’s constricted part. The traverse rod has regular wire loops to guide threads to the reel.

The traverse rod rapidly crosses the reel’s silk while reeling. Each reel holds four ends. The cocoon ends are collected with a stick after cooking the floss. The charka gathers the cocoon filaments in one hand and passes them through the tharapatti. After passing through the tharapatti, two threads are crossed and fed to the charka reel through the distributor guide. A separate turner manually rotates the thread on the reel. Cooked and brushed cocoons with filaments enter the reeling basin and reeler. A reel bench hook near the basin holds clear filaments. (Source: blog.paradisefibers.com) Due to its uneven denier, this reeling method cannot produce high-quality silk. Since cocoons are kept in large numbers at high temperatures in the basin, reeling cannot be maintained uniformly. This method reels in even inferior cocoons, resulting in inferior silk.

The disadvantages are that the boiling and reeling processes cause the basin water to become dirty and coloured, making the raw silk dull. Therefore, the reeler must refill the basin four to five times a day and these breaks result in loose ends.

The cottage basin has small overhead reels and re-reeling equipment. (Source: ashden.org)

2. Cottage basins or domestic basins

- Domestic Basin

The domestic basin improves raw silk quality to compensate for charka reeling system flaws. The domestic basin unit has two reeling basins and one cooking basin on a convenient height platform. To cook and transfer cocoons to the reeling basin, the cooking basin is placed directly in front of the two reeling basin unit. The reeling basin receives cooked cocoons from singlepan cooking. - Cottage Basin

Cottage basins are widely used in reeling, and the cooking unit has three or four basins in a row. Cooking does not disturb reelers, and the table holds 4 to 6 reel basins. Copper sheet reeling basins measure 45 x 25 x 7,5 cm. A tap from the cooking unit’s water drum supplies hot water for the reeling basin. The transmission shaft, drive wheels, and croissure frame are made of wood or iron. Each basin reel has four to six ends. Each basin has jettebouts for filamet attachment. Each basin has its own travellette croissure frame. The reel frame is a one-metre-long, angle iron or wooden frame parallel to the reel bench.Reel benches are 150 to 170 cm tall from the ground, so the knotter can move freely in the passage and knot threads. Drive wheels on a transmission shaft turn the power reels. The transmission shaft has a handle for reel rotation and a traverse mechanism with gears and a cam to move the traverse bar. This multi-end basin is slightly better than the domestic basin. The cottage basin has small overhead reels and rereeling equipment. The rest resembles a domestic basin machine.

Figure 1. Formation of thread from raw silk. (Source: Agarwal, 2014)

- Multi-end reeling basins

Multi-end reeling machines produce thread on small reels at a slow speed. Reeling slowly breaks the thread, resulting in less waste and easier re-reeling. It helps make better silk mechanically, and the reeling does not strain the reeler. This reeling technique has revolutionised design and operation. The multi-end unit automatically cooks cocoons. The reeling unit has two parallel rows of basins with small overhand reels. The reel bench is tall enough for workers to sit on stools and reel. Deep rectangular reeling basins with a copper and tin interior, 10 to 12 cm wide are used. Jetterbouts with equal reeling ending in each basin, an overflow drain, and a travellette croissure are all required.Reels on the multi-end machine range in diameter from 60 to 75 cm. The light metal or hard frame machine has six hard wood reel bars. Each reel has a round stainless steel or brass rim around the reel bars. Connecting gears from the main shaft drive the reels over a carrier shaft. A mechanical brake on the shaft stops all reels when needed. Each reel has a stop motion device that automatically stops when encountering large slugs and waste in raw silk thread. All reeling machines have porcelain button thread guides with a tiny thread aperture. It has speed regulators, and the vibration-free machines last longer. The multi-end machine improves reeled silk quality, productivity, and waste.

The multi-end reeling machines produce thread on small reels at a low speed. (Source: silks.csb.gov.in)

References

CGSpace. (2007). Sericulture in East Africa. Japan Association for International Collaboration of Agriculture and Forestry. Available at: https://www.jaicaf.or.jp/fileadmin/user_upload/publications/FY2007/report-2007_1_e.pdf

Agarwal, A. (2014) 1 silk reeling, Academia.edu. Available at: https://www.academia.edu/7988066/1_SILK_REELING