Pickled red cabbage is shredded red cabbage canned or bottled in brine. Red cabbage (Brassica oleracea capitata) is most frequently used and should be packed as soon as possible after receipt from the field or cold storage. Good-coloured varieties with tight heads are used.

Process description

Harvesting of cabbage

Cabbage is harvested by cutting the heads from the stems with sharp knives or blades, either manually or mechanically.

Cooling of the harvested cabbage

Water losses (wilting) occur as a result of transpiration (moisture evaporates from the surface cells), respiration, and surface damage which exposes the product to air and further losses.

Products must be cooled as soon as possible after harvesting to ensure that the best quality is maintained.

Most harvested products will keep for a few hours at moderate temperatures, but if they are transported over long distances, the products must be kept at low temperatures. Hydro-cooling is used where the product can be sprayed or dunked in refrigerated potable water (16 to 20 °C). Dunking the product in potable water at this stage also gets rid of some of the residual dirt, dry leaves and other debris.

The product must be transported and handled carefully to ensure minimal damage. Bruises may result in soft spots, off-flavour development and sites for insect infestation or enzymatic reactions. Products can be transported vertically or horizontally through mechanical methods, for example, a simple moving conveyor or baskets in which the product can be loaded. Visual inspection can be performed while the product is conveyed.

Roller conveyors rotate the product to ensure visibility on all sides and are used especially for inspection. Some products are transported in potable water, where the water acts as a cushion against any possible mechanical damage. The potable water can be recirculated after filtration and treatment. A flume is the simplest, where a trough (V-shaped) is filled with running potable water. Pump systems can also be used

where products are transported in a closed pipe to where it will be used, and the product and potable water is then separated. Potable water is defined as water free from suspended matter and from substances that could be deleterious to the product or harmful to health.

Inspection and sorting of cabbage

This is done to select the best suitable raw materials for manufacturing the value-added end product. Inspection is done on arrival of the cabbage at the processing plant to select the best suitable raw materials for manufacturing the value-added end product. The outer leaves are removed manually while all infected, injured and overmature heads are also removed. The product must adhere to the minimum quality requirements to ensure optimum quality and processing efficiency.

Sorting and inspection are very labour-intensive practices.

Washing of cabbage

The product is washed in water baths (large containers filled with potable water which must regularly be changed to minimise the chance of contamination spreading) or by immersion in agitated potable water baths. High-pressure water sprays may also be used to ensure that all surfaces are cleaned.

Salt may be added to the water to remove insects and their larvae.

Sorting and trimming

This is done to select the best suitable raw materials for manufacturing the value-added end product.

Trimming is the deliberate removal of unwanted or unfit fractions of a food product. Sorting is done to select the best suitable raw materials for manufacturing the value-added end product. The product is trimmed and the fibrous stalks removed; any damaged or immature sections must also be removed. The quality of the product and adherence to pre-set quality standards (colour, shape and size) must be controlled carefully. Only heads with minor defects can be trimmed.

Cutting for pickling

The washed cabbage is quartered or chopped finely, depending on the final product required. The cut surfaces must be clean cut across the cells otherwise it will result in a limp, discoloured product which will not allow for even heating during further processing. Only stainless steel knives, hand driven cutting devices or automatic cutters made from stainless steel should be used.

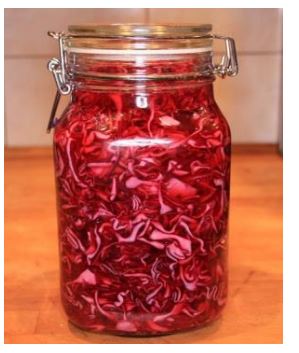

Commercially pickled red cabbage. (Image Source: londonprobe.com)

Care must be taken to ensure that these pieces of equipment are regularly cleaned and disinfected to minimise the spreading of contamination. The cutting edges must be sharpened at regular intervals. Blunt cutting edges will damage the product, exposing a lot of cells to air and also tearing the product resulting in a poor, unappealing appearance of the final product. Work surfaces must also be cleaned regularly and disinfected to prevent cross-contamination and possible build-up of micro-organisms.

Cleaning and washing of the cut cabbage

Washing with potable water removes insects and other impurities located inside the cabbage head. Undesirable, under-sized bits and pieces can also be removed through washing.

Brining

The cabbage can be brined using a solution containing about 10% salt. The brine may be slightly acidified with lactic acid. The cabbage is left in the brine for 12 to 18 hours (overnight) and then drained. Brining should not be done in corrosive containers such as metals, but rather in containers made of glass, earthenware and certain plastics. Brining flavours and preserves the product.

Desalting cabbage (optional)

The cabbage strips can be briefly rinsed in potable water and allowed to drain thoroughly. The final product is then less likely to be too salty.

Filling and packaging

The cabbage is filled into suitable, noncorrosive or lacquered containers and covered with packaging liquid (pickle solution). The liquid can be added to the shreds in bulk and allowed to stand for a few days before retail packaging, or packed directly into the retail containers. Bulk packaging minimises the effect of minor variations in cabbageto-liquid ratio on the equilibrium acidity of the finished pack.

The packaging liquid consists of natural or distilled malt vinegar, spirit vinegar, acetic acid, or any desired combination according to the final product requirements. Spices can also be added. The spices are usually in concentrated extract form and may include ginger, pimento, black pepper, chillies, cloves, and coriander.

The container is closed or sealed hermetically. Products that require further heat processing should be vacuum-sealed using evacuating or steam flushing techniques.

Heating of pickled cabbage (optional)

The pickled cabbage may be given heat treatment in the final retail container to pasteurise or sterilise the product and thus extend the shelf life and eliminate the need for refrigerated storage. Products may be pasteurised by a mild heat treatment that raises the internal temperature of the product to 66 °C. The time of exposure needed to destroy spoilage organisms and pathogens depends on the acidity of the product, container size and type of packaging material. Pickled cabbage should have a pH below 3,7.

This necessitates a heat treatment of 30 minutes at 66 °C. As the temperature increases, the time is reduced, within the limits set by the packaging container. Pasteurisation can be performed in open or closed cookers.

Commercially pickled red cabbage. (Image Source: londonprobe.com)

More severe heat treatments may also be applied. High-temperature short-time (HTST) treatments are generally used to sterilise the product and are usually performed in retorts. Still retorts (batch retorts) may be vertical or horizontal. Horizontal retorts are easier to load and unload.

The retort is closed and steam is pumped into the closed vessel. The time/temperature combinations depend on the heat and pressure resistance of the container. A heat treatment of 12 minutes is required at 100 °C, while only 3 seconds is necessary at 121 °C for commercial sterility. Inefficient heating results in premature spoilage of the product. A preservative such as sulphur dioxide may be added in recommended doses to extend the shelf life.

Cooling of heat-processed pickled cabbage

After heating, the product requires to be cooled to below 40 °C with cold water. The first stage of cooling takes place in the retort (for sterilised products) and further cooling takes place once the containers have been removed. Cooling prevents over-heating which could result in loss of sensory quality.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.