When it comes to grain processing there is no other choice than Alvan Blanch. With more than 70 years of engineering experience, their innovative designs and systems exceed others on the market.

Christabel Blanch, Sales Manager for Africa at Alvan Blanch, explained at AgriTech expo in Chisamba, Zambia that Alvan Blanch is a family-owned global business. They manufacture grain dryers and grain processing equipment.

With clients in six continents and more than 150 countries they continue to expand and have recently started partnerships in South Africa as well.

Their solutions help farmers to take their crops from harvesting to secure storage in the most efficient manner possible. This means cleaning, drying, storage, and even processing.

Christabel said: “Everything we make is British engineered and manufactured. We have state of the art CNC systems in our factories in the UK and everything comes from the UK. We work closely with a team of design engineers and produce quality systems that are built to last.”

She added that the most important thing for them is to engineer systems that suit their clients’ needs and the different markets.

“That means we have a broad range of systems. In terms of drying systems we start off with simple batch systems for two tonnes per batch, to suit cooperatives or small-scale farmers. They are very affordable.”

The company also produces grain commodity trading drying systems for some of the largest names in trading.

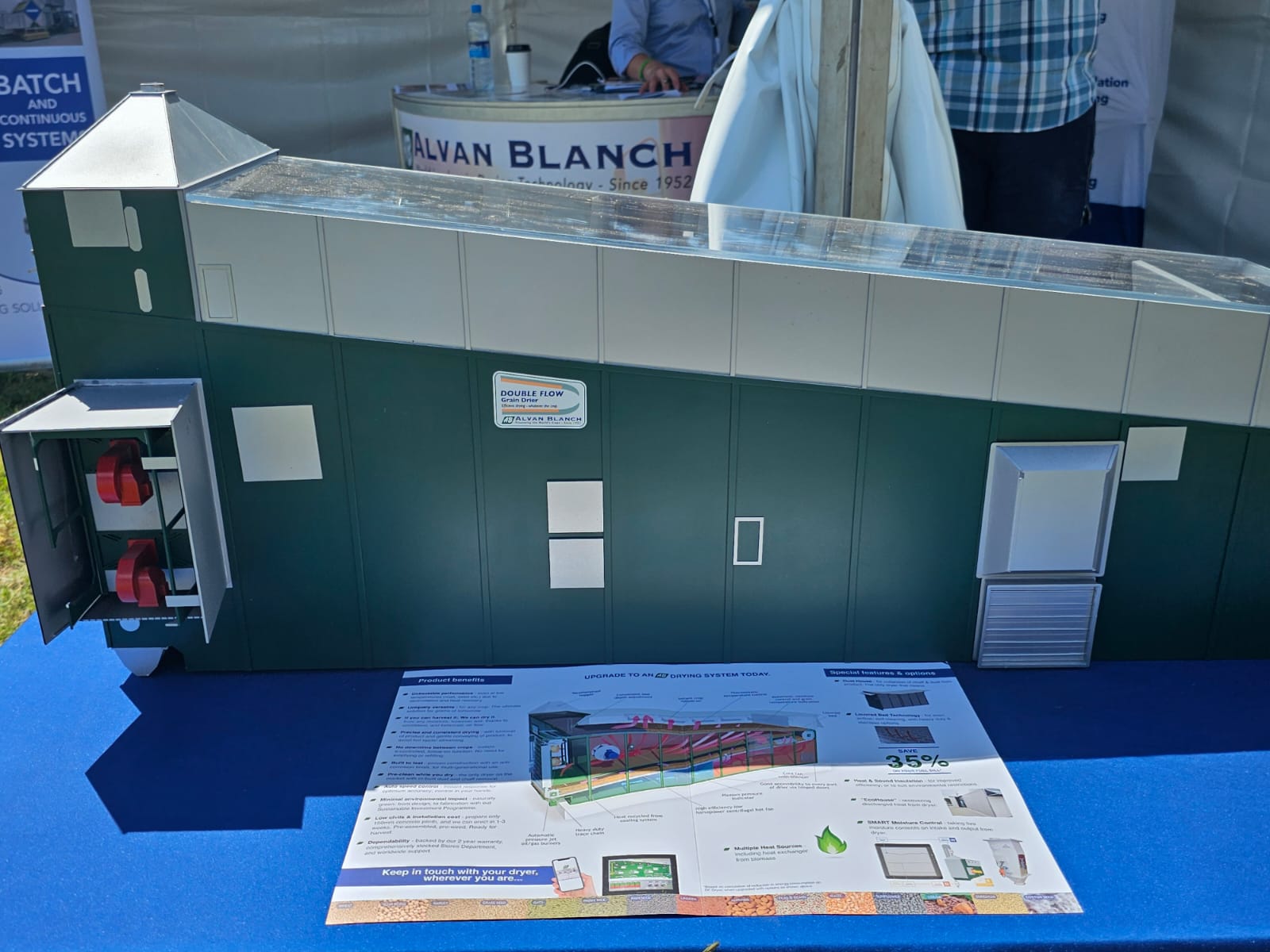

- A miniature representation of the double flow dryer from the top

- A miniature representation of the double flow dryer from the front.

Alvan Blanch expanding globally

They want to build appropriate systems designed to suit every aspect of the market.

When her grandfather started the company, he used to travel to Nigeria to sell their products to the Nigerian market. These days they have engineers based in East Africa and West Africa and technical hubs in both Uganda and Nigeria.

“In Zambia we work directly with clients and we have clients in Chipata, Mkushi and several other regions as well. Zambia is an interesting market; it is clear the maize market is a complicated but incredibly important one.”

Christabel says four years ago Zambian farmers did not see the need for grain dryers, but they have since realised that drying grain enables them to get the next crop in the field quicker, because they can harvest sooner. With the country sometimes experiencing late rains as well, the grain dryers make perfect sense.

Alvan Blanch dryers can dry any crop from any moisture content.

Christabel Blanch, Sales Manager for Africa at the family-owned grain processing company, Alvan Blanch, talking to clients at the AgriTech expo.

The leaders in grain drying technology

Their leading dryer is the double flow dryer. This dryer has two dry beds, one on the top and one hidden inside.

“It is the only dryer like it on the market. Unlike other dryers it does not rely on the grain moving in a continuous and consistent manner, because grain does not always move like that. Especially if it is non granular or when it is very wet. Then you have the problem of over- or under drying.

A levelling device ensures the depth of the grain depending on the moisture level. A fixed louvred bed system with overlapping louvres allow even airflow throughout.

A chain on either side of the dryer also moves across the bed, this chain has a series of slats that pull the products slowly across the fixed bed which is angled at 4 degrees. The bed has a very narrow gap for air, and this means you can dry small grains like canola or even oil seeds like sunflower.

The whole top section is for drying and the second half of the second section is also for drying. The cooling section at the end ensures your grain comes out already cooled down. From there it can be augured into a silo or transferred into handling equipment.

This is also the only dryer that cleans as well as dries. It aspirates as the product falls to the second bed; this means the product turns over entirely and is dried evenly. But the air also blows through the grain ensuring that dust and other particles are caught in a dust house that can be installed at the back of the machine.

The system can work with any heat source like gas or diesel burners, biomass boilers or biomass furnaces.

“Anything that has hot air, water, or steam can be used. It is simple to install and only needs a 150-mm thick concrete floor. It will last at least two generations.”

For more information about Alvan Blanch’s amazing grain systems, visit their website at www.alvanblanchgroup.com.