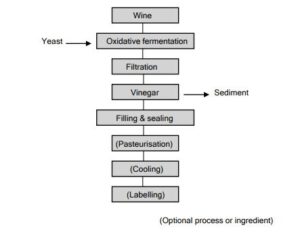

Vinegar is the sour liquid obtained by naturally fermenting the juice of any fruit, cereal or sugar substances. Fermented grape juice, that is wine, is used as the starting material to which the vinegar plant (yeast culture) is added. The wine undergoes an acetic fermentation by micro-organisms of the Acetobacter spp., which converts the alcohol to acetic acid.

Process description

Fermentation of wine for vinegar

Wine is pumped into fermentation tanks or wooden barrels. The tanks are insulated to ensure that an even temperature is maintained during the incubation. Small and medium processors make use of a stock solution that is referred to as the mother of vinegar or the vinegar plant. It consists of a tank with some vinegar to which fresh wine is added, and left to ferment. The barrels must contain some air to allow for oxidative fermentation to take place.

This is a slow process and the reaction will stop naturally when the acidity reaches 6 to 8%. When the process is complete, about half of the vinegar is drawn off and, fresh wine is added and the process repeats itself. Largescale production involves inoculating wine with the acetifying bacteria under controlled conditions with abundant air supply to undergo the fermentation reactions. This usually takes between 1 and 2 days. The resulting raw vinegar is filtered and pumped to storage vats (often containing beech chips) where it matures for several months.

The plastic material used must be resistant to the acid level of the vinegar and not contain substances that will migrate to the vinegar.

Filtration of grape vinegar

The vinegar is filtered to rid the solution of any suspended matter present to give a clear coloured liquid. A rotary vacuum filter can be used. A rotary vacuum filter allows for a continuous clarification process. A filter cloth is attached to the surface of a perforated drum to which a vacuum can be applied. The drum rotates slowly and a pre-coat of processing aid (filtration aid) is applied. The vinegar is sprayed on the outside of the drum and passes through the processing aid and cloth to the inside from which it is pumped.

Red wine vinegar. (Image Source: cocinayvino.com)

Filling and sealing of grape vinegar

The vinegar is filled into retail plastic bottles or large barrels/tanks. The plastic material used must be resistant to the acid level of the vinegar and not contain substances that will migrate to the vinegar. The containers are hermetically sealed. The containers used may be pre-printed or undergo labelling after sealing.

Pasteurisation of grape vinegar (optional)

The packaged product may be pasteurised in hot water using batch heaters to raise the internal temperature to 85 °C for three minutes to produce a commercially sterile product and thus extend the shelf life.

Cooling of grape vinegar (optional)

The pasteurised product is cooled to approximately 25 °C by passing the containers through a cold water misting tunnel or by immersion in cold water. In either case, care must be taken not to give the containers a thermal shock by using too cold water in order to prevent the cracking of containers. The bottles are allowed to dry naturally or are blow-dried and stored at ambient temperatures.

Labelling of packaging (optional)

The packaging material or containers that are not pre-printed are labelled and coded with the necessary information. Various labelling and coding systems are available, depending on the type of label and container used.

Various labels. (Image Source: jessicagavin.com)

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.