Sweet potato sugar syrups are made from sweet potato starch, which is converted into a range of different types of sugars by means of special enzymes. The manufactured syrups can be used to replace more expensive cane or beet sugar in the confectionery industry.

Sweet potato sugar syrup is not only a very economic option but offers a wide variety of products with different properties, which can be manufactured to suit specific needs.

Process description

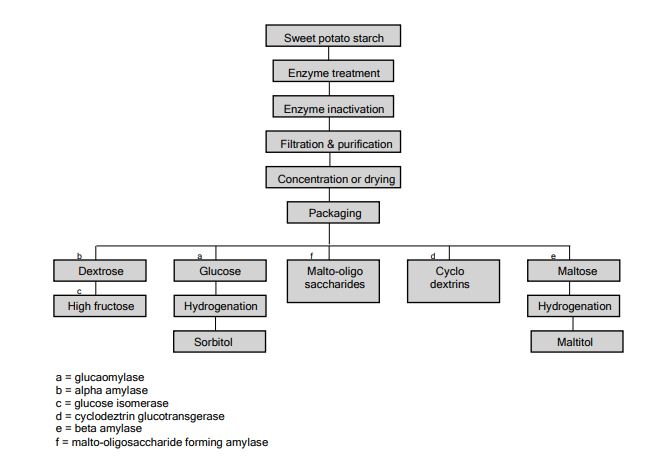

- Raw material for sweet potato sugar syrups: Different types of sugar syrups can be manufactured from sweet potato starch as shown in the process flow diagram. The specific properties of the enzyme used to determine the type of sugar to be formed. The processing technique for each type of sugar is different and therefore only a basic processing procedure will be discussed here.

- Enzyme conversion of starch to syrup: Specific enzymes are added to the starch slurry at an optimum temperature and left for a certain period during which the starch is converted into sugars. Different types of sugars such as glucose, fructose, maltose et cetera may be formed depending on the type of enzyme used and processing parameters such as time and temperature. These enzymes are specially prepared and commercially available. The extent of saccharification may be tested with a tincture of iodine. A second enzyme treatment with a different type of enzyme may be necessary for the production of certain types of sugar syrups. This is usually done after inactivation of the first enzyme.

- Enzyme inactivation: The enzyme activity is stopped as soon as optimum saccharification has taken place. This is usually accomplished by means of a heat treatment.

- Filtration: The syrup is filtered through activated carbon, using an ion exchange method to remove impurities.

- Concentration: The liquid syrup is concentrated by vacuum evaporation or ordinary boiling until it is concentrated to the specified requirements. The syrups may also be dried into a powder form.

- Packaging of sweet potato sugar syrups: Packaging is defined as the containment of a food product in a protective barrier that prepares goods for transport, distribution, storage, retailing and end-use. Packaging requirements for sugar syrups are basically protective containment with easy dispensing features. Powdered syrups are highly hygroscopic and require moisture-proof packaging.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.