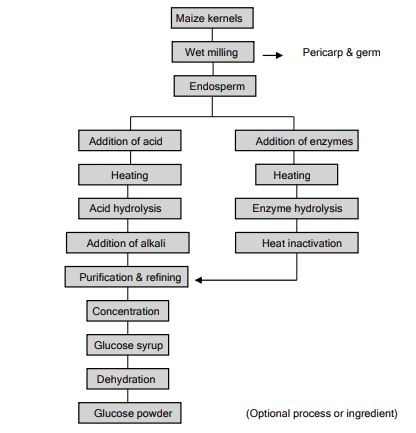

Maize sweeteners and syrups are manufactured from the starchy endosperm of maize using a conversion process known as hydrolysis. This hydrolysis process can be chemical (by means of strong acids), or enzymatic, or a combination of the two.

Various types of maize syrups can be produced, including glucose, maltose, dextrose and fructose. The type of sweetener produced depends on the processing conditions and hydrolysis agents used.

This article will deal primarily with the production of glucose syrups and powders. Starch is composed of thousands of glucose units that are linked together to form long chains. When these links are broken, starch is broken down to smaller units which can be single glucose units, two glucose units combined (maltose) or more than two glucose units combined (dextrose). Single glucose units may also be converted into its isomer, fructose, which is much sweeter than glucose.

This conversion process is also done by enzymes. The various products formed from starch during hydrolysis are classified according to their dextrose equivalent (DE) value. This is a measurement of the reducing sugar content that is expressed as a percentage of the total dry matter content.

Process description

Milling of maize for syrup production

Before maize starch can be converted into syrups, the maize needs to be wet milled and the endosperm separated from the rest of the components.

Acid hydrolysis of starch

Strong mineral acids such as hydrochloric or sulphuric acid are used to acidify the starch slurry to pH 2,0. This is done in a reactor. Once the optimum pH has been reached, the steam pressure is increased. This causes the gelatinisation and depolymerisation of the starch to facilitate hydrolysis. The mixture is then left to react under controlled temperature and pressure conditions until the desired DE value is reached. The process is stopped by adding alkali to raise the pH to between 4 and 5.

The acid hydrolysis process was the traditional method of preparing maize syrups, but has been replaced by enzyme hydrolysis. There are several reasons for this. First, the acid process is a random process; in that it causes random hydrolysis of the links between glucose units, and thus produces unpredictable products through an uncontrollable process. Second, it requires various purification treatments to separate the chemicals from the syrup.

Enzyme hydrolysis of maize for syrup

Various starch hydrolysing enzymes are available to the processor, such as alpha- and beta-amylase, glucoamylase, amyloglucosidase and glucoisomerase enzymes. Each enzyme has a different hydrolysis pattern and specific optimum operation conditions. These enzymes can be used alone or in combination on fresh maize starch or partially acid-hydrolysed starch. The enzymes are added to the gelatinised and depolymerised starch slurry in a powder or capsule form and left to react until the desired DE value is reached.

The enzyme activity is stopped by a high heat treatment. The drastic improvements in enzyme technology have made enzymatic hydrolysis the more popular choice today. Enzymes are very specific and can overcome the limitations of acid hydrolysis. They can produce a wide spectrum of syrup products that vary in composition and functional properties. In this way, syrups can be tailormade for a specific purpose.

Maize syrup. (Image Source: iheb.com)

Purification of maize syrups

It is necessary to remove the chemical agent used in acid hydrolysis as well as various non-carbohydrate components that detract from the clarity, colour, and stability of the syrup. A centrifugation or filtration process is applied first to remove large impurities. Inorganic ions may be removed by a demineralisation or ion exchange treatment. Protein impurities are considered serious impurities with regard to the colour of the syrup. These need to be removed by adsorption on activated carbon. Two types of activated carbon may be used; steam activated or chemically activated carbon.

Concentration and dehydration

The purified syrup is concentrated to about 60 to 80% dry matter content (weight basis) to give the required concentration and viscosity of the syrup. At this stage, various additions such as sulphur dioxide or anti-foam agents may be added to improve its handling characteristics. The syrup may also be dehydrated and crystallised to produce a powder.

Final product – maize syrup

Maize syrups are inexpensive sweeteners (compared to cane and beet sugar) with various functional properties that make them popular for application in the chocolate, sweet and confectionary industry. Their sweetness value and functional properties vary according to their composition, making it a very versatile ingredient.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.