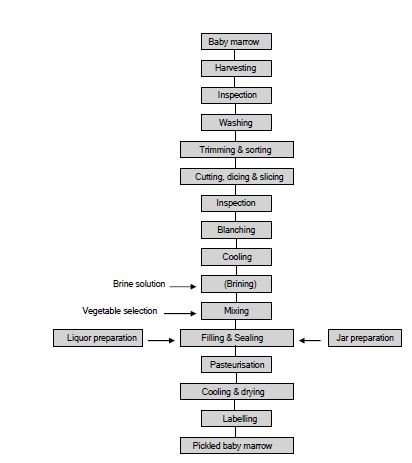

Baby marrows (courgette or zucchini) are common ingredients in vegetable pickles. It can either be pickled alone or in combination with other vegetables such as onion, gherkins, cauliflower, green beans, or carrots. The product is preserved by the low pH ((<4,5) of the packaging liquid and a pasteurisation treatment. It is sealed in suitable containers such as glass jars.

Harvesting of baby marrows

Baby marrows are harvested at a very immature stage when the rind is tender and seeds are underdeveloped. The fruit reach harvestable size 4 to 6 days after pollination and therefore require regular picking. Baby marrows are harvested by hand, every other day, for several months. Harvesting should be done by cutting rather than snapping off the fruit to minimize physical damage of the fruit. Poorly trimmed stem ends promote post-harvest decay. Pickers also remove the attached blossom in the field.

Pickers often wear gloves for protection against the thorny leaves and stalks, but also to reduce the damage caused to fruits by fingernails. The baby marrows are placed in plastic crates for easy transport and should be removed from the field as soon as possible.

Inspection and sorting

This is done to select the best suitable raw materials for manufacturing the value-added end product. The harvested baby marrows are inspected and any damaged, infested, rotten or off-colour baby marrows are removed along with any foreign matter such as sticks and blossoms.

Washing of baby marrows for processing

Baby marrows are washed to remove adhering dirt, soil and any other unwanted deposits. Water baths filled with potable water or agitated washing drums must be used.

Trimming and sorting

The baby marrows are inspected for damage. Any damaged, immature or misshaped areas are trimmed away using sharp stainless steel knives. The baby marrows are size sorted according to length and diameter.

Cutting

The baby marrows are sliced, diced or cut into strips, according to requirements. Manually operated apparatus or automatic cutting equipment can be used.

Inspection

The pieces are inspected to ensure that only the correct length and thickness is selected. No defects, black spots, slivers or pieces of stalk may be present.

Blanching

Blanching is a short heating process whereby food products are heated to a certain temperature that is high enough to inactivate the enzymes responsible for undesirable changes in colour and flavour. Vegetables are living plants that continue to respire after harvest. Enzymes start to break down tissues as soon as the vegetable is removed from the plant, producing waste products which are an ideal growth medium for micro-organisms, which causes changes in the taste and flavour of the product. Blanching prevents enzymatic and microbiological deterioration by inactivating enzymes and killing plant tissue. The main disadvantages of blanching are the loss of water-soluble vitamins and minerals.

This should be controlled by keeping the exposure time as short as possible. During commercial blanching, the product should be heated to the required temperature as quickly as possible to minimize the softening of the tissue. There is a variety of blanching methods to choose from, including water blanching and steam blanching, individual quick blanching (IQB), vacuum steam blanching, microwaves and integrated blancher-coolers. Steam and IQF blanching would be a good choice for baby marrow pieces, since water blanching tends to make the product soggy.

Drying and cooling of blanched pieces

The blanched pieces are dried to maintain uniform colour of the product, and to prevent it from becoming soggy. Moisture is first removed by using dewatering screens where the product is spread out in a thin layer on mesh screens and the moisture is allowed to evaporate. To increase the drying efficiency, cool air can be blown over the product. This not only dries but also cools the product and preserves the texture of the blanched pieces by preventing extended heating.

Brining

The baby marrow pieces are brined by immersing in a 10 to 15% salt solution. The brine may be slightly acidified with lactic acid (0,5%). Brining may continue for 1 to 5 days before the vegetable pieces are removed and rinsed with potable water to reduce the salt content of the pieces to 5 to 6%.

Mixing baby marrow pieces with additional ingredients (optional)

Popular additions to baby marrow pickles are cauliflower, green or red peppers, and onions.

Filling and sealing

The baby marrow/vegetable mixture is packed tightly into suitable, wide mouthed glass jars that have been properly cleaned. The packaging liquid is added, ensuring that all the ingredients are completely covered to prevent deterioration of the vegetables. The packaging liquid is prepared from natural malt vinegar, spirit vinegar, acetic acid or any desired combination according to the final product requirements. The addition of spices, such as turmeric and caramel, to the vinegar for added flavour is optional. The addition of a sweetener in the form of granular sugar, glucose syrup or artificial sweetener is also optional. Artificial sweeteners are useful in creating a product suitable for diabetics.

The quantity of sweetener to be added is judged according to taste. The addition of sweetener should be declared on the packaging label. The containers are hermetically sealed with self-venting, acid resistant lacquered metal closures capable of forming a vacuum seal. A small headspace is left at the top of the jar. Heating the packing liquid prior to filling does slightly raise the temperature of the product, but is not necessarily effective in decreasing the required heat dosage of pasteurisation since the majority of the pack consists of the vegetable pieces which are filled at room temperature. The final acidity of the product should be below pH of 4,5 and thus only requires pasteurisation for long term preservation.

Pasteurisation

Pasteurisation entails the controlled and limited heating of the pickle in sealed containers that are capable of forming a headspace vacuum upon cooling. It is impossible to give specific time and temperature requirements in a general report like this since sufficient pasteurisation depends on the size and dimensions of the container, the starting temperature, the type of equipment used, the type of product and pH. As a general rule, the point of slowest heating in a mixed pickle with a pH below 4,5 should be held at 71 °C for 15 minutes. However, it is essential to institute the most rapid and efficient heating method possible to ensure that the product is not overheated, resulting in softening of the vegetables and a generally poor quality product. Pasteurisation is necessary to ensure a long shelf-life product. This is achieved by the heat destruction of spoilage micro-organisms and heat inactivation of most enzymes that cause darkening, softening, clouding, sedimentation and flavour deterioration in a pickled product.

Pasteurisation also removes air in the product, thus minimising oxygen-dependent spoilage mechanisms. Pasteurisation can be performed by various methods and equipment. Batch operations commonly use steam cabinets or batch retorts while continuous operations use continuous steam cabinets or hydrostatic retorts. The hydrostatic retort consists of a “U” tube with an enlarged lower section where the pressure is maintained by a column of water at the inlet and outlet (the two arms of the “U”). Hot water fills one of the legs while cold water fills the other. The containers are placed on a chain conveyor and fed into the hydrostatic retort via one of the arms.

The containers are progressively heated by hot water rising in the tube. At the bottom of the inlet tube, the containers are moved into the sterilisation section where the temperature is increased to 115 to 121 °C. The containers follow an undulating path through this section to ensure sufficient contact time and temperature exposure. After the required time in the sterilisation section, the containers are transported to the outlet column where they are progressively cooled. 13. Cooling of pasteurised pickles Pasteurisation should be followed by rapid cooling.

Cooling prevents overheating that would result in loss of sensory quality. The jars are cooled to below 50 °C with cold water. The first stage of cooling takes place in the cabinet/retort by replacing the hot water with cooled and progressively cooler water. Further cooling takes place once the containers have been removed. Alternatively, the containers can be quickly cooled by passing them through misting tunnels. Cooling of glass jars should be gradual to prevent thermal shock that would result in cracking of the jars. The containers are allowed to dry naturally or blow-dried with hot air blowers prior to labelling.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.