Grinding

Grinding involves exposing dried products to friction and pressure to produce a fine powder. Before extraction of the oil can take place, the dried rhizomes are ground.

Size reduction of dry food products:

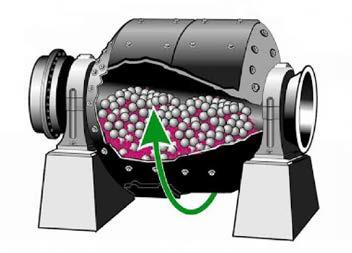

Ball mills:

The ball mill consists of a slowly rotating, horizontal steel cylinder that is half-filled with steel balls. The balls have a diameter of 2,5 to 15 cm. At low speeds, or when small balls are used, shearing forces predominate, while when larger balls are used or at higher speeds, impact forces predominate. The rod mill has rods instead of balls in order to overcome problems associated with the balls sticking in adhesive food products.

A ball mill. (Image: energosteel.com)

Disc mills:

Disc mills come in a large number of designs, but all types employ shearing forces for fine grinding or shearing and impact forces for coarser grinding:

a.Single-disc mills are mills in which the food product passes through an adjustable gap between a stationary casing and a grooved disc that rotates at high speed.

b.Double-disc mills are mills in which two discs rotate in opposite directions to produce greater shearing forces.

c.Pin-and-disc mills are mills that have intermeshing pins fixed to either the single disc and casing, or to double discs.

Ground ginger. (Image: nuts.com)

Hammer mills:

The hammer mill consists of a cylindrical chamber, which is fitted with a toughened steel breaker plate, and a high-speed rotor is then fitted inside the chamber. This rotor is fitted with hammers along its length. When the mill is in operation, the food is disintegrated mainly by impact forces as the hammers drive it against the breaker plate. In some mill designs, the exit from the mill may be restricted by a screen and the food product remains in the mill until the particles are small enough to pass through the screen apertures.

Roller mills:

In this mill two or more steel rollers revolve towards each other and pull food particles through the space between the rollers (the nip). The main force involved is compression, but when the rollers are rotated at different speeds, or if the rollers are fluted, in other words have shallow ridges along the length of the roller, an additional shearing effect is exerted on the food product. The size of the nip may be adjusted for different food types, and overload springs protect the mill against accidental damage from metal or stones.

A roller mill. (Image: monsterbrewinghardware.com)

Distillation

Distillation is the purification of a liquid using evaporation and condensation processes. Essential oil is distilled from the dried, ground rhizomes by means of steam distillation.

In the oldest and simplest method of steam distillation, a direct flame heats a vessel containing water and chopped or crushed plant material. The water vapour as well as volatile oil are then recovered by a water-cooled condenser. In the more modern method, steam under pressure is passed through the prepared plant material and the volatile oils are condensed along with the water. Steam may also be bled directly into the boiler for distillation.

A small ginger distillation plant to extract essential oils. (Image: kosbest.com)

In order to avoid thermal decomposition of lower-boiling constituents, the steam pressure is increased only gradually. The distillation temperature with the use of water or steam at atmospheric pressure is usually slightly under 100 °C and can be reduced further by drawing a partial vacuum on the still.

Centrifugation

Centrifugation is the process by which liquid samples are spun around at high speed to cause the accelerated settling of particles in suspension. The water and oil phases are separated from one another.

Liquid-liquid centrifuges:

The simplest type of liquid-liquid centrifuge is the tubular bowl centrifuge, which consists of a vertical cylinder, 0,1 m in diameter and 0,75 m long, that rotates inside a stationary casing at between 15 000 and 50 000 rpm, depending on the diameter. The feed liquid, such as animal and vegetable oils, is introduced continuously at the base of the bowl and the two liquids are then separated into annular layers, the denser liquid being nearer to the bowl wall. The separated liquids are discharged separately through a circular weir system into stationary outlets.

However, as the relatively thick annular layers cause some disruption to the flow patterns, better separation is obtained through the use of a disc bowl centrifuge as this centrifuge forms thinner layers of liquid. The disc bowl centrifuge consists of a cylindrical bowl, 0,2 to 1,2 m in diameter, which contains inverted metal cones or discs.

An industrial centrifuge used in the processing of ginger oil. (Image: alibaba.com)

These discs have a fixed clearance of between 0,5 and 1,27 mm and rotate at speeds of between 2 000 and 7 000 rpm. The discs have matching holes that form flow channels for liquid movement. The feed liquid is introduced at the base of the disc stack and the denser fraction then moves towards the wall of the bowl, along the underside of the discs, while the lighter fraction is displaced towards the centre along the upper surfaces.

The liquid streams are then removed continuously by a weir system at the top of the centrifuges similar to that of the tubular bowl system.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.