Boreholes are vital for deep soil water extraction. Much like everything else on your farm, taking care of your borehole will ensure that it takes care of you. That is why you need quality parts that are both effective and durable.

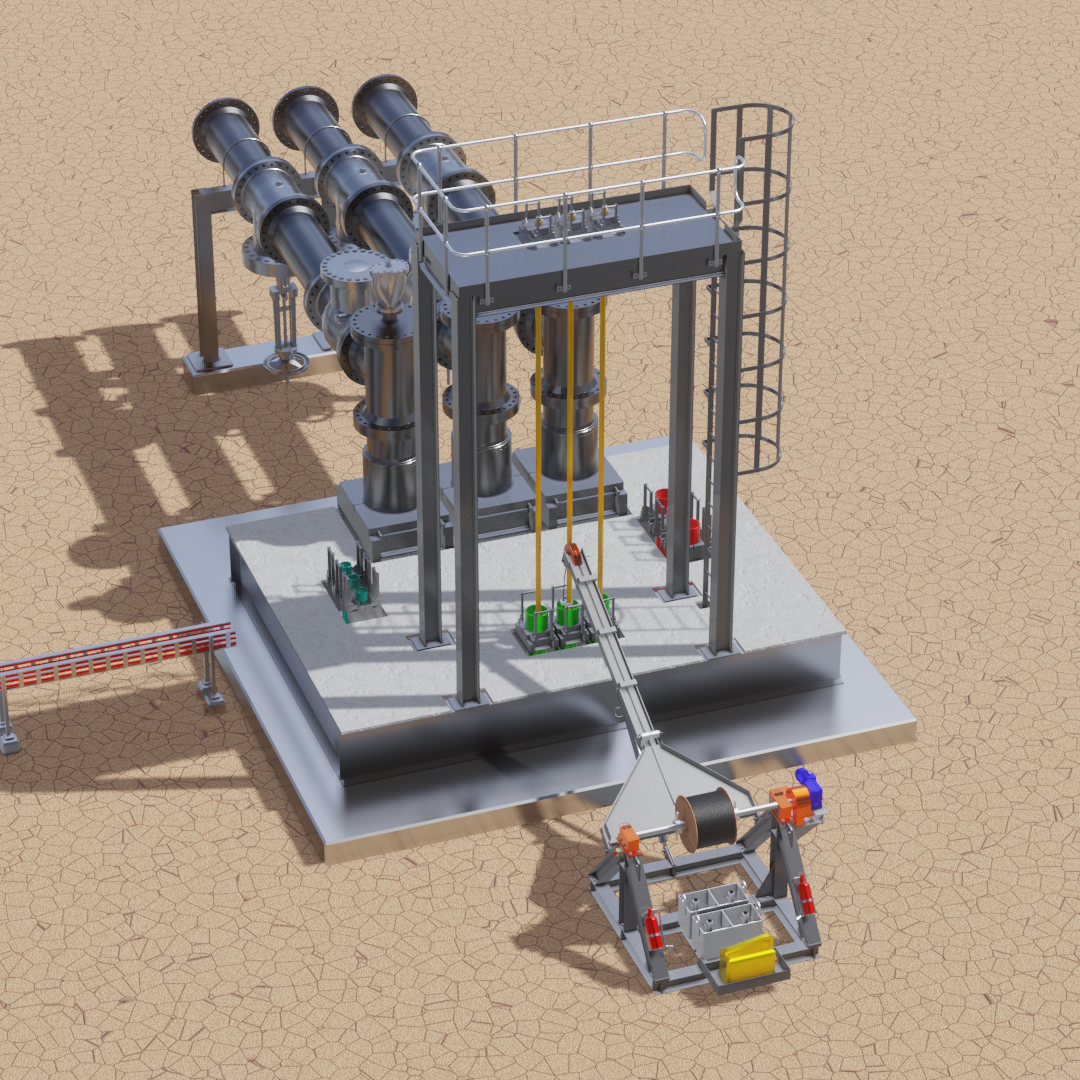

Carl Hamm PPS, supplier of specialised pumps and pipes for the agricultural and mining industries, together with their German partner and manufacturer, STÜWA, is geared to ensure your borehole is well managed and will continue to deliver pure water through superior equipment.

Two products specifically produce proven effective results:

The slotted bridge well screen

A well screen is a part of the casing at the bottom of a well or borehole that stabilises the structure of the hole while also preventing debris such as rocks and dirt from the surrounding borehole wall from entering the water supply system.

What makes this product effective is the shape of the holes in the screen. The holes appear to have bridge-like structures over them, ensuring that water can still pass through the holes, but preventing any rocks and sand from doing the same. The slotted bridge well screen is produced according to internal STÜWA standards.

“STÜWA bridge slotted screens and casings are at the cutting edge when it comes to stability and material quality,” says Chris Munnick, CEO of Carl Hamm PPS. By using a well screen, it stabilises the aquafer strata and helps water flow into the borehole at a consistent rate, therefore protecting the area around it.

Depending on wall thickness of each well screen, slot widths are approximately 0,5 mm or more. The wall itself can be up to a thickness of 12 mm. Screens are available in plastic and stainless steel, making them rust resistant and durable.

The ZSM riser connection

A wide range of connections are available, but the ultimate decision rests on the technical requirements of your borehole or well. Depending on the circumstances in which these connections will be used, the following factors need to be considered:

- tensile strength,

- collapse resistance,

- outer diameter, and

- installation guidelines

“What makes this coupling strong and unique is that, unlike a screw-in pipe, it doesn’t need to be exactly straight to prevent a leak, and it is connected in seconds,” Chris explains. “The fact that there are no screws that can damage the pipe is also a plus.”

A ZSM connection has a restraining pin that slides into the slot to form a perfect seal. This pin acts as a hook that holds the opposite part of the connection perfectly in place. Since there are no grooves, as with screw connections, the seal is tight and prevents sand from making its way into the thread. Furthermore, water cannot escape past this type of connection’s seal ring.

The riser pipe connection has a pin that slides into the slot to seal the connection.

The ZSM connection is quick and easy to install and can handle a lot of pressure — up to 40 bar! The pipes can fit into wells of up to 300 m deep and 250 mm in diameter.

This slim, thin connection is the ideal choice for any project where there is little wiggle room. The couplings are made from stainless steel, meaning that they are durable and rust-resistant — you will not need to replace tarnished connections because they last exceptionally long.

German engineering that offers durability and longevity

Carl Hamm and STÜWA share a similar beginning. Both are family businesses that are currently being managed by the fourth generation of their respective families. Together they strive to deliver customers with products of proven efficacy and durability. All products are developed in-house in Germany and shipped straight from the factory.

Hard as a diamond

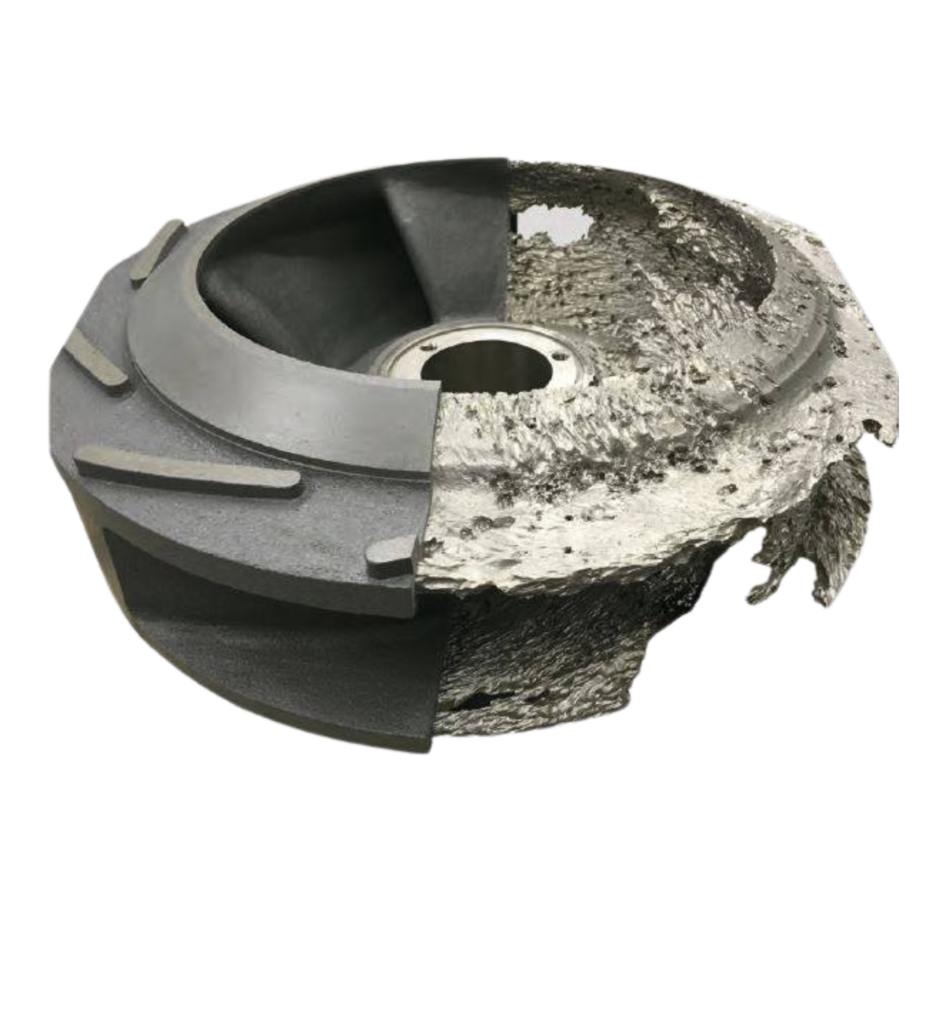

Carl Hamm PPS is a proud distributor of SICcast.

SICcast produces the complete range of MC pumps and coats parts affected by strong erosion, abrasion and/or corrosion in liquid media based on patented silicon carbide materials.

SICcasts combine silicone carbide and epoxy resin to make corrosion-resistant, moulded parts.

This is an artificially produced industrial material with a diamond-like hardness. Silicon carbide (SiC) is a special mixture of epoxy resin cast into precision moulds and formed under a vacuum.

It started with the casting of several pump parts for the MC series and afterwards for the MCC series of affiliated company DÜCHTING pumps.

The important key feature of the material is the simultaneous resistance against corrosion and abrasion.

Based on the hardness of silicon carbide (9,7 on the Mohs’ scale and close to the hardness of diamond), and the high filling grade of the components, it has very good results in casting new pump parts and in coating worn spare parts. The benefits of the SICcast-technology are longer service lives and lower costs compared to new parts.

For more information on the products and services that Carl Hamm provides, contact Chris Munnick on +27(0)10-900-2005 or send an e-mail to chris@carl-hamm.co.za. Visit their website at www.carl-hamm.co.za.