Across the globe, there is a shift towards becoming more sustainable. Companies are finding ways to meet these criteria and help customers do the same. Knittex also believes in caring for the planet and trust their customers value this too.

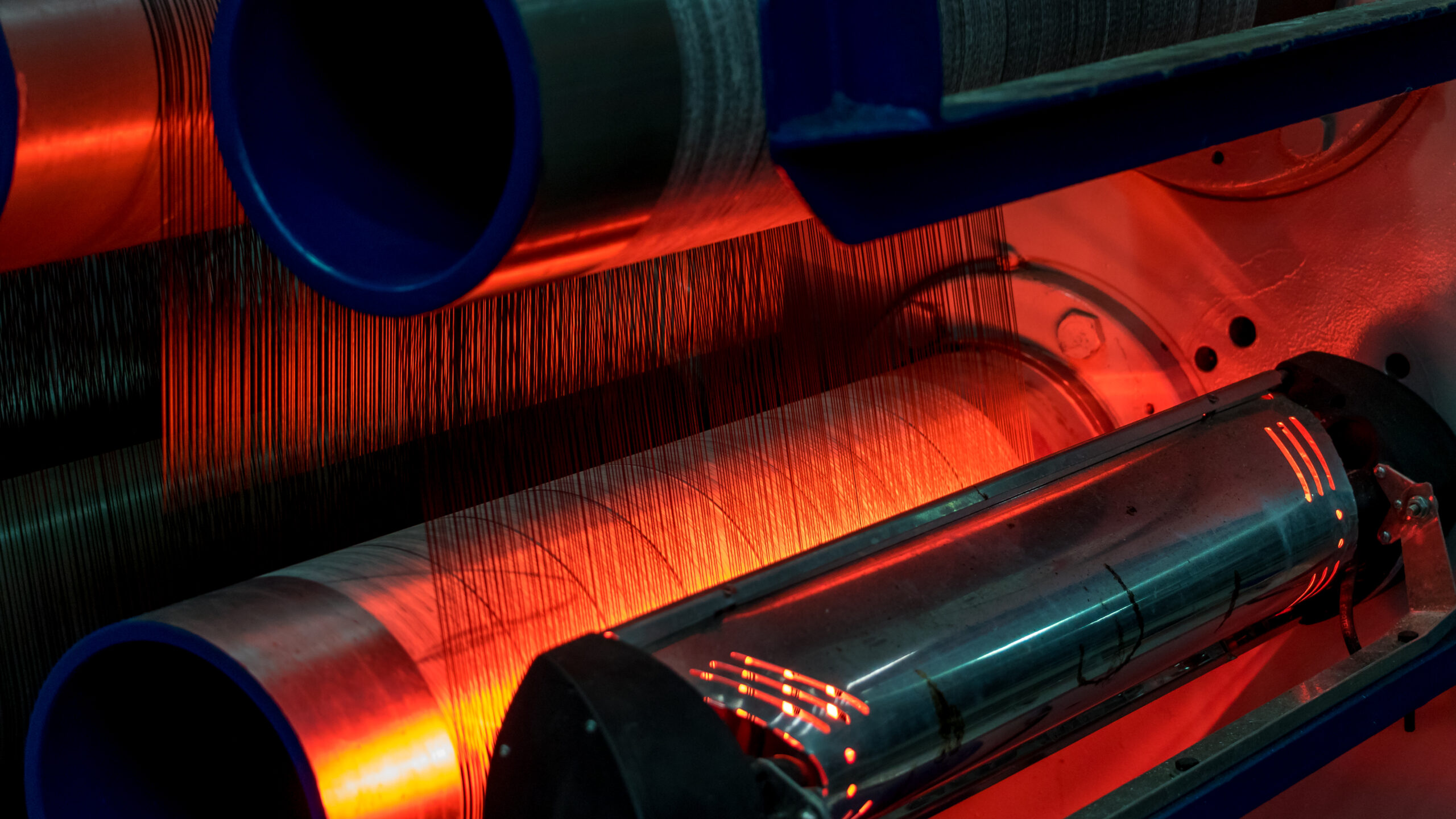

Manufacturing synthetic fabric for agricultural use, Knittex uses HDPE to create their products. HDPE, in very basic terms, is a kind of plastic. Now, how can a company whose main business is manufacturing plastic products be “green” and help their clients to be more sustainable? Let’s take a closer look.

Knittex textiles are made from HDPE which means it can easily be recycled.

Sustainability starts at home

“The recyclability of our product is driven inside our factory and the processing of waste and rejects back into a usable product is actively being practised,” says Bill Blake, Regional Sales Manager at Knittex. “We have a Health and Safety Officer employed full time, who is vigilant and ensures that we adhere to environmentally friendly practices in our operation. We make use of a closed water system, with a purifying system to ensure minimum evaporation and wastage of water, through recycling.

He explains that the environment and resources are critical in the markets that Knittex trades in. “It is important that we all do our part in the sustainability chain. Our customers’ drive to buy from a sustainable company will drive us to become even better at it,” Bill says.

Outside of the factory, the product can be washed and recycled into furniture made from plastic slats. “We deal with companies incorporating the exposed recycled shade net into moulded products, by means of injection moulding.”

There are efforts in the factory to save water through a closed water purifying system.

Helping farmers and customers be more sustainable

Farmers can not only save up to 25% of water consumption by growing crops under shade net, it also increases the effectivity of spray programs.

“By incorporating shade net over crops, such as fruit trees, the pack out percentage can increase from 60% up to as high as 95%, depending on the crop and the climate. In the end it effectively also reduces the hectares you need to plant outside versus inside to get the same yield,” he points out. “Education in the management of growing a crop under net versus open land is crucial to ensure that our customers get the optimal benefit. It is a reality that the harshness of climatic conditions is increasing, with higher temperatures, severeness and frequency of hailstorms, making our product even more relevant than ever before.”

When it comes to the industrial and decorative net ranges, the use of the Colourshade Z25, eXtreme 32 and DriZ to cover human-made building materials can assist in the reduction of the urban heat island effect.

Evaporation of water from swimming pools, reservoirs and dams happen through wind or excessive heat. “By covering your swimming pool, reservoir and/or dam with our shade net (Code 80 Pool Blue, Code 80 or Colourshade) the evaporation rate is drastically reduced,” he adds. “Savings in water consumption and reduction in use of chlorine, in your pool, will be evident.”

Knittex agricultural and decorative net carries a warranty against UV degradation for 10 years. This means that the net needs to be replaced less often than other brands that do not carry this guarantee.

“It is important to note that we have had product available in the industry for more than 20 years and although the strength is not the same as a brand-new product, the test results of the 20-year-old fabric, has shown a 42% retained strength after 20 years exposure to the harsh elements,” Bill boasts.

The synthetic fibres that are made for weaving agricultural netting is strong and can survive the UV onslaught by the sun for at least a decade!

Sustainability when the product is replaced

Normally when people invest in agricultural net that has a promise to last a minimum of ten years, they do not really consider what happens to the plastic when it is replaced. The good news is that this material can be recycled. In fact, many recycling facilities can accommodate the large quantity that is removed from the structure.

Bill explains that there are manufacturers of other products that use these materials, recycling the net into an array of products. “Manufacturing plastic furniture and pipes for example.”

With regards to future plans that Knittex has to continuously work towards being sustainable include their ongoing research and development to explore possibilities for recycling product. Furthermore, the brand might investigate alternative yarns to replace the current HDPE. “Working smarter with sustainability at the forefront is our goal,” he concludes.

Working smarter with sustainability is at the forefront of Knittex’s goals.