A dam wall may seem to be a simple construction, but when you are dealing with the incredible force that water exerts, you have to be very careful with your calculations, building procedures and particularly with your building materials.

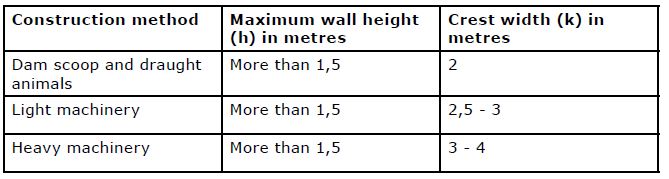

Crest width of a dam wall

The crest width of the wall is determined by the implements used for the construction. The crown width must be at least 1½ times the width of the implements with which the dam is being built, in order to get good compaction. The crest is also made in a certain relation to the height of the dam wall (see Table 1).

Table 1: Crest width versus construction method

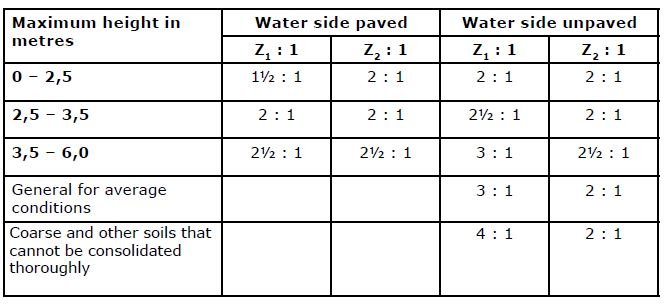

Slopes of a dam wall (Table 2)

Table 2: Determining the slope of a dam wall

The factors that determine the slopes of the dam wall are as follows:

1.Seepage lines through the wall.

2.Angle of repose of soil: The slopes of earth walls must be flatter than the angle of repose or else the soil will shift down along the wall until the above condition is reached.

3. Danger of erosion by wave action: The size of the waves on a dam is in a specific relation to the size of the surface of the basin. The wave action is also the strongest in the direction of the prevailing winds. Certain building soils are also more subject to erosion than others. If a wall is unpaved on the water side, it must have a relatively flat slope.

4. Stone pitching or rip-rap: Where paving material is easily obtainable near the building site, the paving of earth dams on the water side must be considered. When the danger of erosion is great, paving is almost the only remaining solution. If a wall must be paved, it is possible to give the wall slightly steeper slopes. Maximum stable side slopes for average building soil (Z1 : 1 water side and Z2 : 1 the rear).

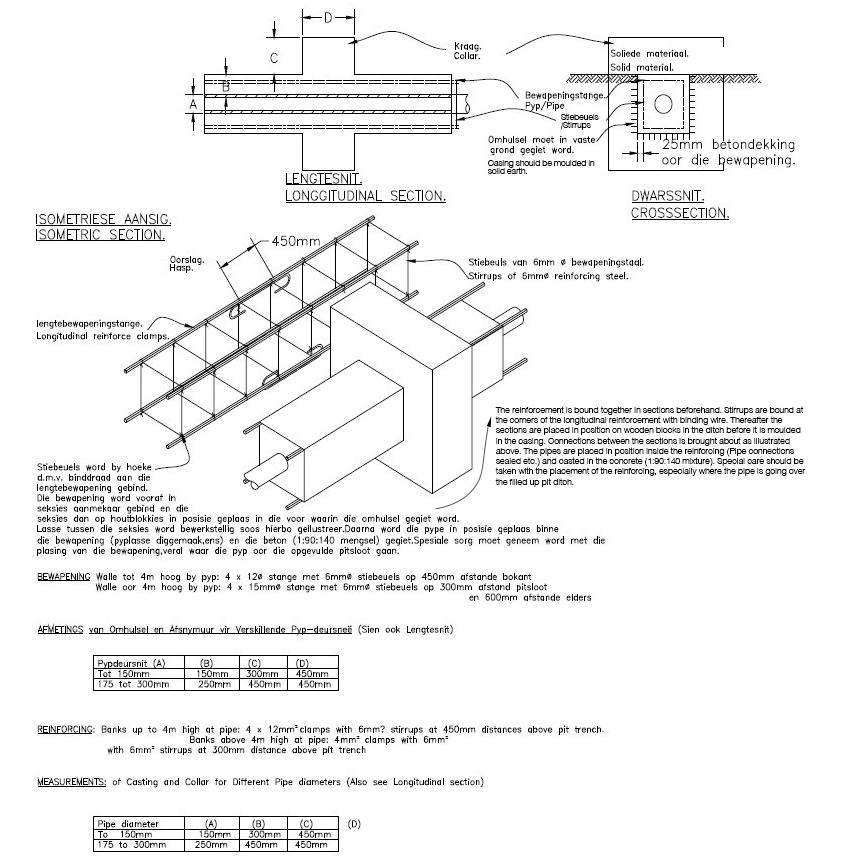

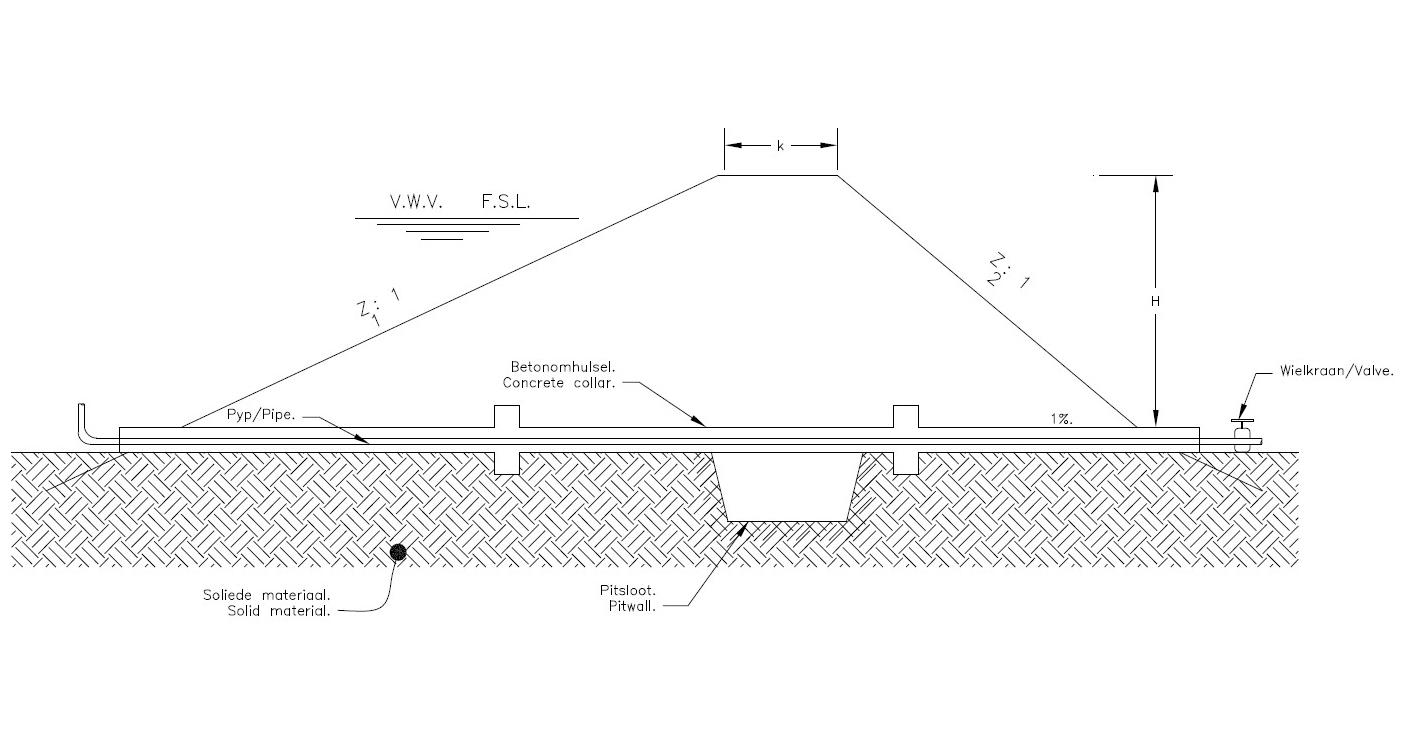

Figure 1: Particulars of the reinforced concrete collar for outlet pipes of earth dams.

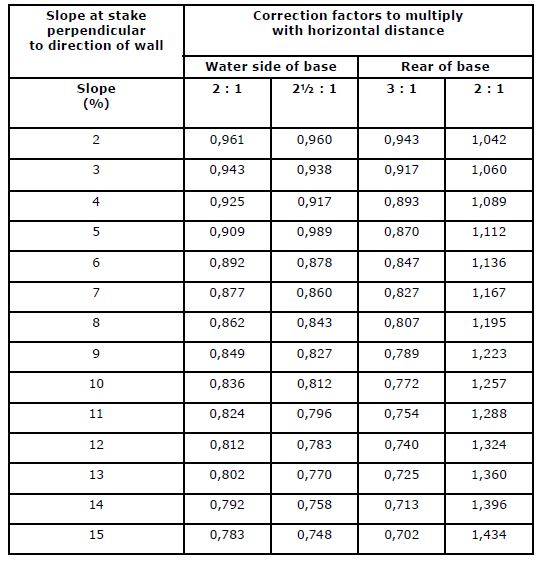

Dam walls against sloping terrains The base width of a dam wall must be corrected by means of the table below, from the centre line, if the terrain slope exceeds 4% (see Table 3).

Table 3: Correction factors for sloping distances of base stakes

Pipe through dam wall

The outlet pipe should always, as far as possible, be placed in undisturbed soil. The opening of the pipe in the dam basin must always be slightly higher than the deepest place in the dam to prevent silting up of the pipe.

Construction of an outlet pipe. Photo: itearthmovers.co.za.

The pipe must have a minimum slope of 1% over its length. Fast closing valves should be avoided to prevent water shock in the pipe.

Table 4:

Concrete collar for outlet pipe

The pipe must be placed in a concrete collar with reinforcing steel. The various measurements needed for the concrete collar, cut-off walls and reinforcing steel for different wall heights above the pipe, are shown and described in Figure 2.

Figure 2: Cross section of pipe with concrete collar through the dam wall.

The wall must be thoroughly compacted with manual compactors against the concrete casing to one metre above the pipe.

A dam wall with a steady slope. Photo: ibbnrd.net.

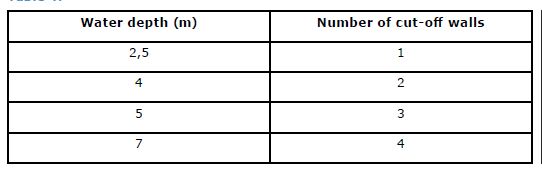

Cut-off walls

Cut-off walls are used to lengthen the seepage line along the concrete casing of a pipe. Table 4 shows the number of cut-off walls prescribed for specific water depths above the pipe. Alternatively, the path of the seepage line must be lengthened by at least 20%

A well designed outlet pipe. Photo: ibbnrd.net.

Published with acknow-ledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.