Spray tips don’t last forever, yet it is extremely difficult to detect wear because it may not be visible. Spray nozzle wear of 10, 20, or even 30% won’t be visible. Using even slightly worn tips is very costly. Water, crop protection product, and labor are wasted, and crop protection product application quality can be compromised.

The spray tip wear depends on:

- Tip material

- Crop protection formulation type (e.g. wettable powder)

- Water quality

- Operating pressure

- Cleaning procedure

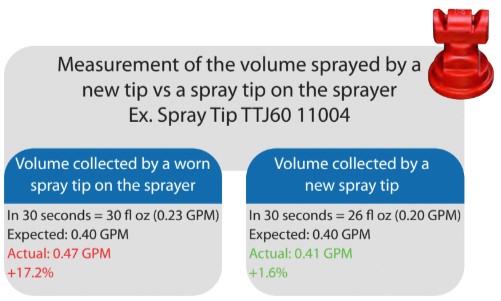

Rather than relying on visual inspection, it is better to compare the ow rate from a used spray tip with the ow rate from anew tip of the same size, type, and pressure. If the ow from the used spray tip is 10% greater or more, replace it (quantitative method).

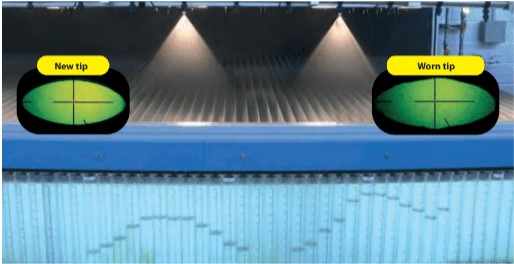

Compare the deposition pattern of a new and used spray tip in a distribution table and check if the used tip pattern shows a different distribution than the new tip (qualitative method).

In the image below it is possible to observe a distribution table comparing a new tip (left) with a worn tip (right) spray pattern. The worn nozzle is spraying 30% over the capacity. Comparing the spray coming from the new and worn nozzle only with our eyes would be hard to detect because the spray patterns look identical.

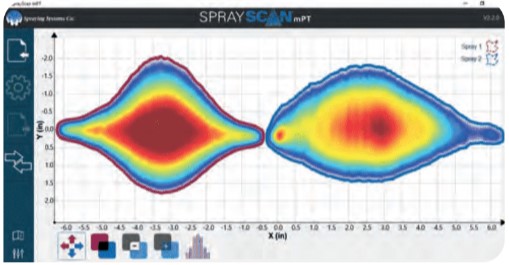

It is also possible to use a software that can compare the spray pattern of a new tip vs a worn tip (qualitative method). In the image below, it’s possible to observe the SprayScan® mPT software comparing the spray pattern of a new tip (left) with a worn tip(right). In this example, the new spray tip has excellent droplet distribution uniformity, preserved deposition at the center, and dissipation towards the edge. The droplets are concentrated at the center of the spray, represented by the red colors. Worn spray tips, on the other hand, present an uneven distribution, represented by the irregular spray distribution color pattern.

For more information about their certified and approved TeeJet spray tips, visit their website at www.teejet.com.