Peppers can easily be pickled in a brine or vinegar solution, alone or with other vegetables and seasoning. The variety of coloured peppers available make attractive pickles. Certain varieties can be pickled as whole pods, while larger peppers are cut into strips.

Harvesting of bell peppers

Bell peppers are harvested by hand into pails that are emptied into bulk bins for transport to the packaging/ processing site. The peppers should be harvested by cutting the fruit from the plant with a sharp knife or scissors, and not pulled or twisted as this can easily damage or uproot the plant. The pickers should be trained to minimise handling damage. The harvested peppers should be transported to the processing site or at least a cool location as soon as possible, since peppers are considerably more susceptible to water loss, sun scale and heat damage after picking than before.

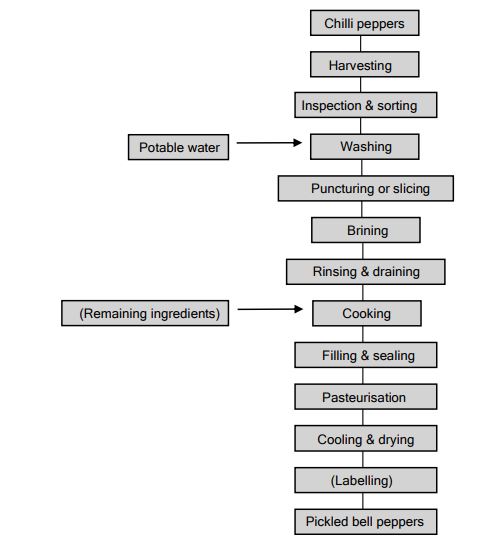

Process description.

The correct stage of maturity for harvesting depends on the use of the product. If full colour development is desired for an attractive display, the fruit is picked at >80% discoloration. Otherwise, the fruit is picked once the mature green (full size) has been reached. Peppers ripen and colour more evenly in greenhouses compared to those cultivated in the field. Field peppers harvested in a green or non-uniform coloured state can be exposed to ethylene gas during storage to promote uniform ripening and colouring, if so desired.

Inspection and sorting of fresh bell peppers

Only the best quality peppers should be used for the fresh market while minor defects and non-uniformities can be tolerated for slicing and dicing purposes. Selection criteria include uniformity in colour, maturity, shape and size, and freedom of defects. Any pepper showing signs of mechanical or insect damage, diseases, rot, or sunscald is discarded.

Washing of bell peppers

The harvested peppers are washed in a water bath assisted with soft rotating brushes or by gentle jet sprays.

Preparation of peppers prior to pickling

Large peppers are cut into long, thick strips. Peppers that are going to be pickled as whole pods are only punctured. The peppers are then submerged in a brine solution (1½ cups pickling salt to 3,8 litres of water) and left to stand for 12 to 18 hours. The brined peppers are removed, stet,

rinsed and again drained thoroughly.

Cooking of peppers prior to pickling

The peppers and remaining seasonings and vegetables are added to vinegar, water, and sugar in a cooker. The mixture is heated and simmered for 15 minutes while stirring occasionally.

Filling and sealing of pickled peppers

The hot pickled peppers and vinegar sauce is filled into hot, clean glass bottles/jars, leaving a small headspace. The bottles and jars are preheated by rinsing them in hot water to avoid giving the glass a thermal shock. The filled jars are lightly sealed by loosely screwing the lids on to ensure that expanding air can escape from the jar during pasteurisation.

Pasteurisation of pickled bell peppers

Pasteurisation entails the controlled and limited heating of the pickle in sealed containers that are capable of forming a headspace vacuum upon cooling. It is impossible to give specific time and temperature requirements in a general report such as this, since sufficient pasteurisation depends on the size and dimensions of the container, the starting temperature, the type of equipment used, the type of product and pH.

However, it is essential to institute the most rapid and efficient heating (and cooling) methods possible to ensure that the product is not overheated, resulting in softening of the vegetables and a generally poor quality product. Generally, a 500 ml container requires to be heated for 10 minutes in boiling water or steam. This can be accomplished by passing the containers through a hot water tank or steam cabinet on a batch or continuous basis.

Commercial pickled bell peppers (Image Source: thenibble.com)

Cooling and drying of pepper pickles

Cooling involves extracting heat from the product to decrease its temperature using an appropriate device such as a heat exchanger and medium such as water, air, or refrigerant. The containers are cooled with water to approximately 30 °C. This is done by immersing the bottles in water baths or by passing them through misting tunnels. The cooled containers are removed and allowed to cool further naturally. Cooling of glass jars should be gradual to prevent thermal shock that would result in cracking of the jars. The containers are allowed to dry naturally or blow-dried with hot air blowers prior to labelling.

Pickled bell peppers.

Labelling of packaging (optional)

The packaging material or containers that are not pre-printed, are labelled and coded with the necessary information. Various labelling and coding systems are available, depending on the type of label and container used.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.