Arno Vlok grows table grapes and stone fruit in outside Riebeeck-Kasteel near Malmesbury in the Western Cape. For the past 23 years he has been relying on Knittex nets to provide protection against devastating hailstorms.

When he bought the farm Welgevonden in 1994, there were wine grape vineyards. “One needs a lot of land to grow wine grapes,” says Arno. “Having grown up with table grapes, I have a passion for it and decided to change over.”

He also planted nectarines, but the first three years harvested next to nothing. The area is situated in a hail belt and during those first years, there was very little to harvest. “It hails at least once a season during August and September. Even a tiny mark grows larger as the fruit develops and renders the harvest unsuitable for export.”

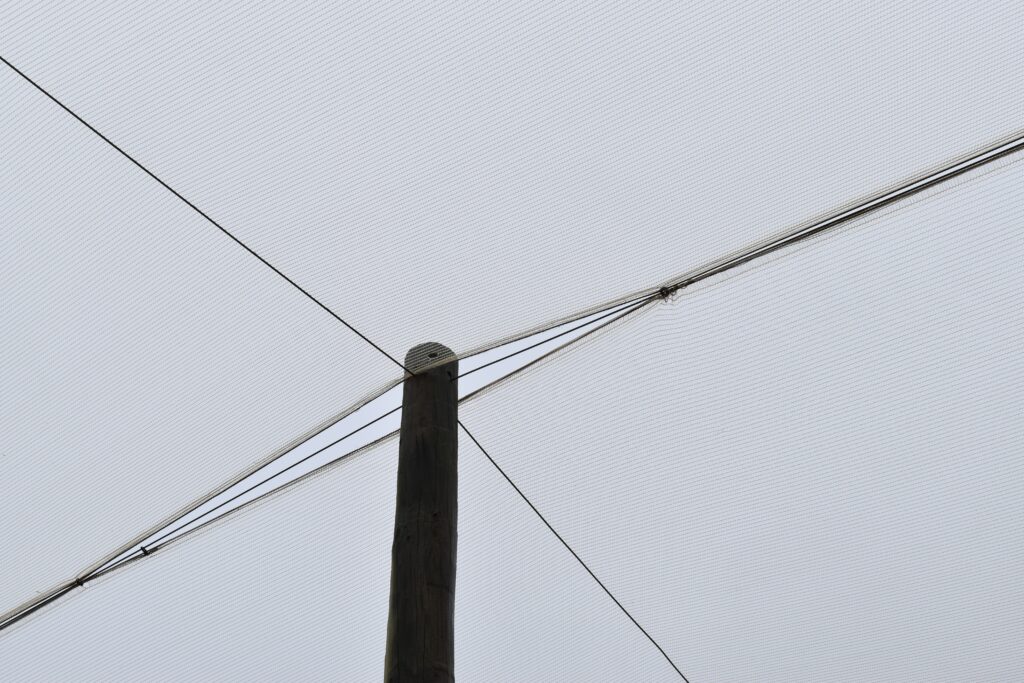

Steel cables are used to securely attach the nets to wooden poles.

Arno considered crop insurance, but it was far too expensive. The only alternative was to install netting. When he planted the next 2,5 hectares in 2000, he approached Knittex for advice. “Now, 23 years later, there are still fruit under that first net.”

At that stage, the construction was not as sophisticated as it is today, and wooden poles and steel wire were used. Knittex still uses poles, but strong steel cables have replaced the wire.

The branches are supported with galvanised wire fastened to crossbars attached to the main anchor poles of the net construction.

Arno Vlok, owner of the farm Welgevonden at Riebeeck-Kasteel near Malmesbury, trusts the expertise of Knittex’s team and quality nets that protected his orchards and vineyards for the past 23 years.

Production shot up

From the onset, production increased from a mere twenty to thirty per cent to ninety per cent. That clinched the deal and Arno decided to cover all future orchards and vineyards with Knittex nets.

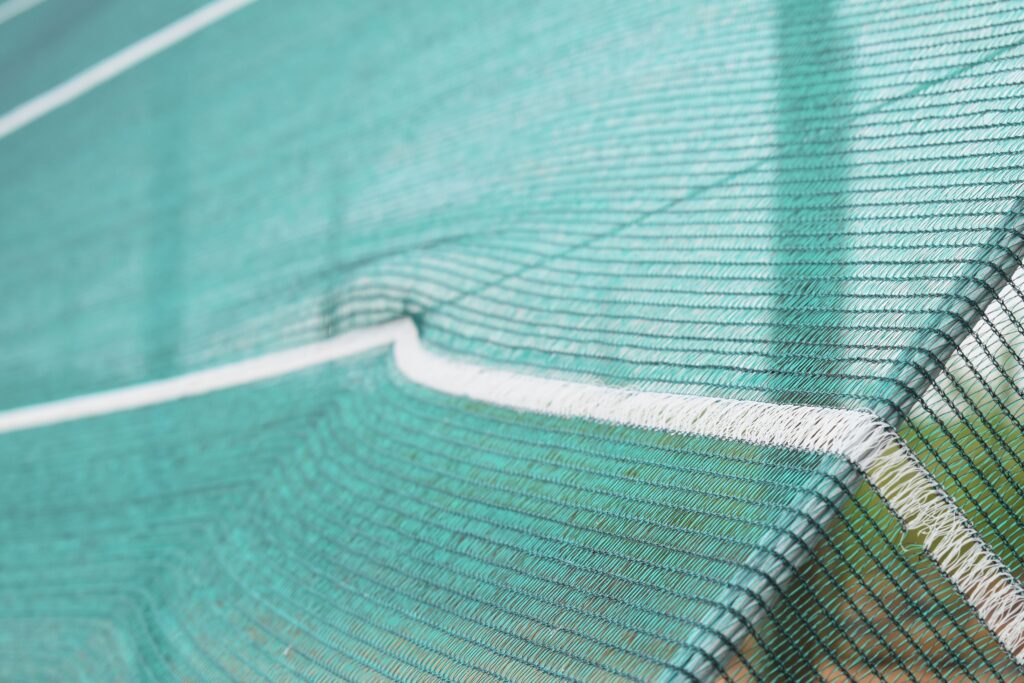

“We use Knittex’s Crystal netting with a shade factor of 4, which is sufficient for this area.”

Arno is very impressed with the quality of the service rendered by Knittex. “Construction is one of the cornerstones of successful netting. The construction and nets must be strong enough to withstand natural elements like hail and strong winds in order to be successful and sustainable. If the construction is faulty, the nets chafe and suffers wear and tear.”

- The nets have a shade factor of 4, which allows rain to penetrate.

- Since 2000, all new orchards and vineyards on Welgevonden are protected by Knittex nets to prevent damage by hail and wind, as well as birds and insects.

- Even a tiny mark caused by hail will eventually grow larger as the fruit matures and render it unsuitable for export.

- Arno Vlok puts his trust in Knittex nets to protect his orchards in the hail belt where his farm is situated.

Supreme quality

The nets must be strong enough to carry the weight of a heavy hailstorm. “Sometimes we have light hail, but when it is a heavy storm, the nets stretch up to a metre under the weight, and recover afterwards.”

He also appreciates the quality of the nets, which are manufactured from high-quality knitted material that is lightweight, flexible, and durable, as well as 100% recyclable. The size of the holes is fixed during manufacturing to ensure for consistent permeability. The nets are also easy to repair should it tear by accident.

Side nets are securely anchored to prevent strong wind from damaging the orchard.

“When a hole appears, the net doesn’t run like a stocking, and neither does it unravel. Holes can easily be fixed,” explains Arno. The nets are guaranteed a lifetime of at least ten years or longer – and in Arno’s case that period stretches 23 years.

The nets create ideal growing conditions, and ‘breathe’ because of its air permeability. The extensive net covering of 15 ha of nectarines, as well as 10 ha of vineyard, protects the trees, vines, and fruit against damage by hail, wind, frost, and rain, and even sun and heat damage.

The size of the holes is fixed during manufacturing to ensure for consistent permeability.

The nets also save water by maintaining humidity and limiting evapotranspiration. The trees are planted on raised beds with drip irrigation on both sides of the tree. Mulch helps to keep the roots cool and the root zone moist. The nets also protect the orchards and vineyards against insects and birds.

Altogether 25 ha of nectarine orchards and vineyard are protected with a flat construction of Knittex nets.

“I bank on Knittex. I have proof that their nets protect my livelihood,” Arno concludes.