The planning and construction of a successful dairy require thoughtful actions and the involvement of various knowledgeable people. Many problems and complaints about dairies come about as a result of poor planning and design.

It is therefore important to obtain expert advice before planning your dairy. A design team should be formed, consisting of an agricultural engineer, veterinarian, a supplier of dairy equipment, a financial advisor and any other person whose advice can be of value to the farmer and who knows the farm, and the construction or operation of a dairy.

Choice of a site and layout

The choice of a site is influenced by the following factors:

- Existing infrastructure of the site. The site must be as close as possible to an electricity supply point, near a water source with sufficient, clean water, and vehicles must have easy access to the site from a main road.

- Suitability of the topography of the site. Thoroughly consider factors such as landslides and drainage. Use natural slopes to ensure good natural drainage.

- Soil characteristics of the site. Avoid filled soil sites, underlying rock layers, sand-drift or clayey soils that swell and shrink.

- Possible problems with pollution. Consider the immediate environment, as well as the position of natural water sources to prevent pollution.

The maximum distance the cows have to walk from the veld to the milking parlour must be considered.

During the planning of the layout of the site, the following factors must be kept in mind:

- Buildings must be placed in such a way that the optimum flow pattern of the product and labour can be obtained. The facilitation of management must be considered at the same time.

- Dairy buildings must be situated where they are visible from the farmhouse.

- When determining the distances between buildings, factors such as fire hazards, ventilation and the spreading of diseases must be considered. Large buildings must be at least 30 m apart to prevent fire from spreading from one building to another.

- The milking parlour must be relatively close to the grazing in order to milk economically. A walking distance of 6 km per day for a dairy cow is considered normal. This means that the grazing must not be further than 1,5 km from the milking parlour (if milked twice daily).

- Dairy buildings must be downwind from the farmhouse, but upwind from the service road depending on the prevailing winds during the day.

- Suitable control of access to the site must be possible.

- Sufficient space must be provided for future expansion. The dairy must not be built too close to natural watercourses, because space is required between the milking parlour and the watercourse for manure dams.

- Thorough consideration must be given to flood watercourses to, from and on the site.

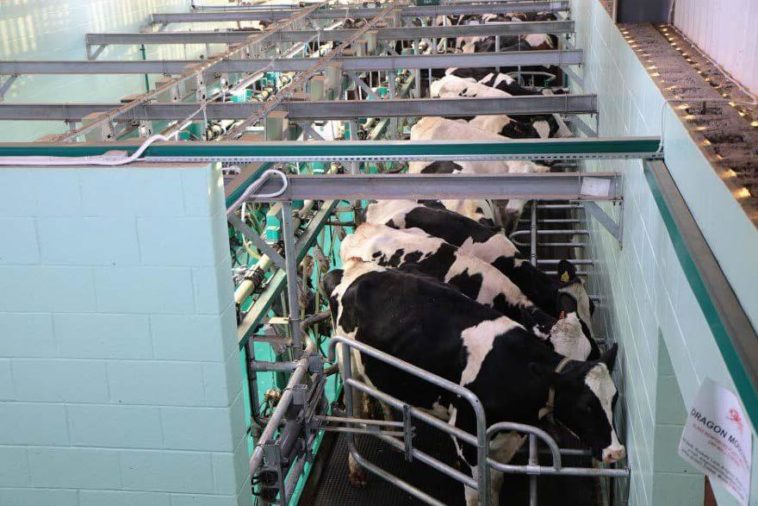

Cows will hesitate to enter a holding pen if the surface is too slippery. (Photo by afnewsagency, Pixabay)

Flow pattern

The flow pattern involves the efficient control of cows moving from the veld to the milking parlour and back with minimum stress for the cow and the labourer. It is not only applicable to corrals and milking parlours, but to the entire dairy. The flow pattern of cows is just as important in intensive systems as in extensive systems.

The larger the herd, the more important the flow pattern. Any delay worsens as the cow numbers increase, with problems increasing if the herd number exceeds 60. Physical barriers such as sharp corners and bottlenecks are easily noticed. It is, however, not easy to notice things that frighten cows and make them hesitate. It can be caused by anything such as a slippery concrete floor on which they find it difficult to stand. It can also be a result of insufficient current protection around the shed, which causes the cows to get light electric shocks when neutral to earth currents (stray currents) are conducted to the cowshed.

As already mentioned, the maximum distance the cows have to walk from the veld to the milking parlour must be considered. These paths must be of good quality. They must be firm, well drained, of even width and without barriers or sharp corners. Any objects or constructions that cause the cows to bunch up, frighten them or push them against fences, influence the flow adversely. Sharp turns in paths must be replaced with a series of wider turns. U-turns hinder the flow of cattle and must be avoided.

Cows will hesitate to enter a holding pen if the surface is too slippery. The concrete floor must have a coarse finish, as cows will move better if they have confidence in their footing. It will be ideal if the cows can enter the holding pen from the back entrance than from the side entrance, so that they can see the milking parlour. A crowding pen also helps in this situation.

A milking parlour must be provided with a proper entrance door, with railings used for directing the cows towards one side or the other, rather than causing them to block the system by hesitating between the two sides. Factors that divert the attention of the cows can also obstruct the flow in the cow pens. Cows in the holding pen that can see other cows being milked and being returned to the veld, will stand lowing rather than queuing to be milked. A wall or solid gate will rule out this temptation.

Illumination is a factor that is often neglected. Farmers must determine how inviting their milking parlours are. Cows do not like to move from light to dark. The ideal is therefore that the milking parlour must be lit and free of barriers.

The exit from the milking parlour is also very important. If it is too narrow, cows are crushed and if it is too wide, they will stand still and socialise. It does not matter how well the milking parlour is designed, as soon as the cows leave the parlour and suitable heading-off facilities are not provided, all aforementioned flow systems will be futile.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.