Many farmers consider precision farming to be the first step on the path to financial success. The confidence and knowledge provided by Jupidex’s precision technology enable farmers to get more out of their limited resources. Because of this, the Jupidex team is dedicated to giving farmers the most advanced precision technology in agriculture.

Since the late 1990s, the Kverneland group (the predecessor to Jupidex) has invested profoundly in developing smart precision agriculture technology that is based on this idea to make crop and livestock farming simpler, more accurate, and easier to manage.

Christopher Laubscher, product specialist at Jupidex says: “When there’s a decision to be made about which type of equipment to purchase, it is not always easy to find the best possible solution among today’s broad market offering. Technology is developing rapidly, with tractors and equipment ever more equipped with high-tech electronics. We understand the complexity behind it, therefore, we are committed to giving farmers simple but innovative ways to deal with the problems they face in the agricultural sector.

“ISOBUS is our standard technological communication component used on all equipment, and the IsoMatch terminals are used for information technology like GPS guidance, control systems, sensors, variable rate technology, automated hardware, telematics, and communication devices. We see it from the viewpoint that you should manage your farm as a prosperous business,” Christopher emphasises.

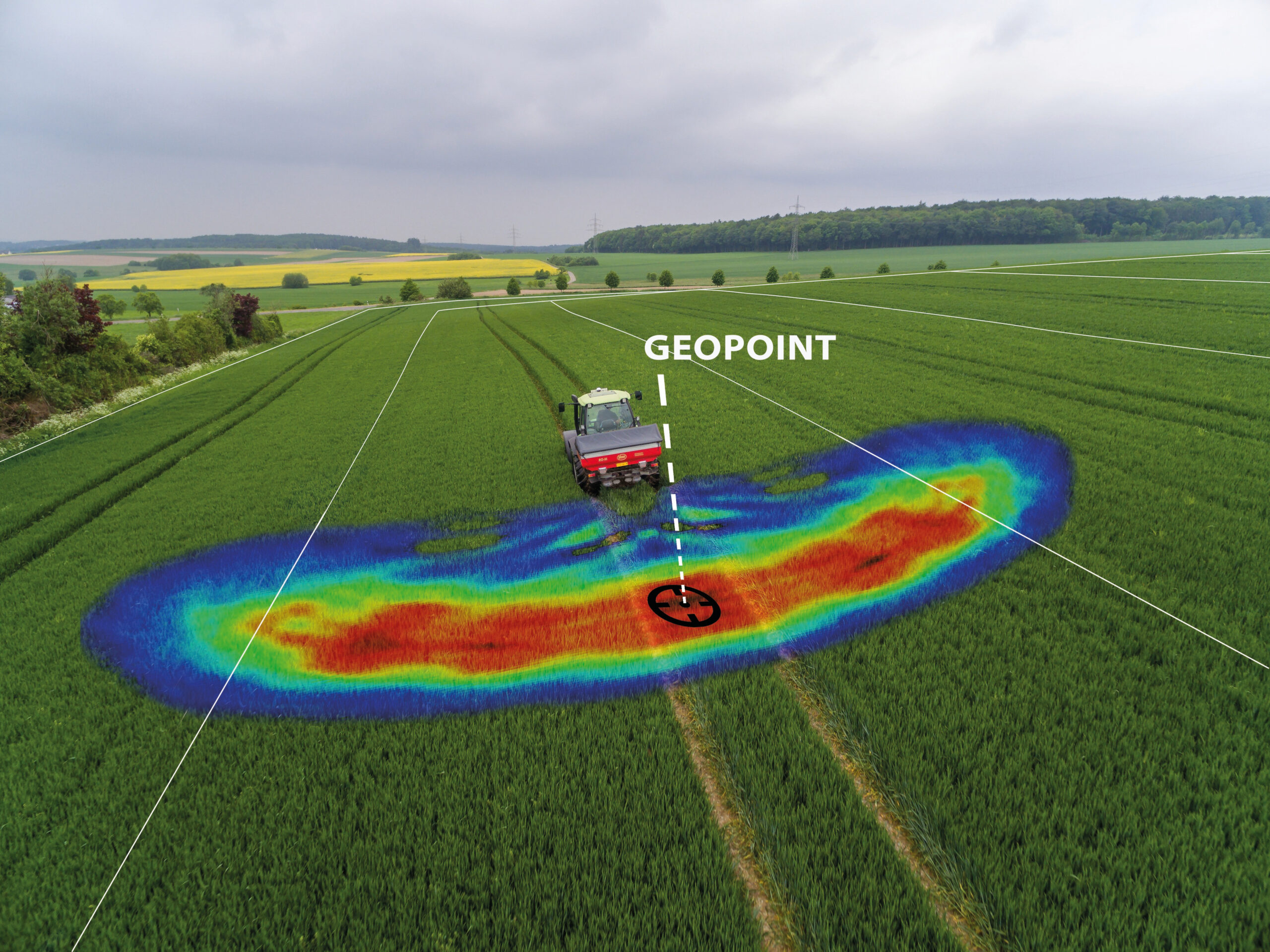

Accurate fertiliser application

The Jupidex team is proud to announce that from now on, all fertiliser spreaders will be sold with a certified Geo licence. Jupidex is the only company offering such a service to farmers.

What does this mean for farmers?

Jupidex’s fertiliser spreaders are ISOBUS-ready, meaning they are compatible and can be used with any tractor’s software. All ISOBUS-compatible Vicon fertiliser spreaders can perform standard variable-rate applications. This is done in accordance with a prescribed map, which works in collaboration with the GPS system. The fertiliser spreader adjusts its placement automatically based on a predetermined and spot-specific map prescription.

Christopher says: “This allows the farmer to work more precisely on his lands, and another advantage is savings in terms of costs on tractors, fuel, and labour. We assist farmers in saving costs and supporting them before, during, and after the spreader is sold.”

All Vicon spreaders are part of the Kverneland range of products and can from now on be identified by the group’s logo on the spreader.

Future-oriented IsoMatch technology

IsoMatch’s precision agriculture technology enables farmers to run their farming operations like a successful business. Time is money and to maximise productivity, time should not be wasted. Therefore, the word timely and IsoMatch go hand in hand.

Smart management of crop protection applications

The Jupidex group is also excited to announce that Waatic kit will be sold as a foundational component with every sprayer in the near future. Making them the only company and exclusive importer in Africa to supply Waatic products directly to farmers.

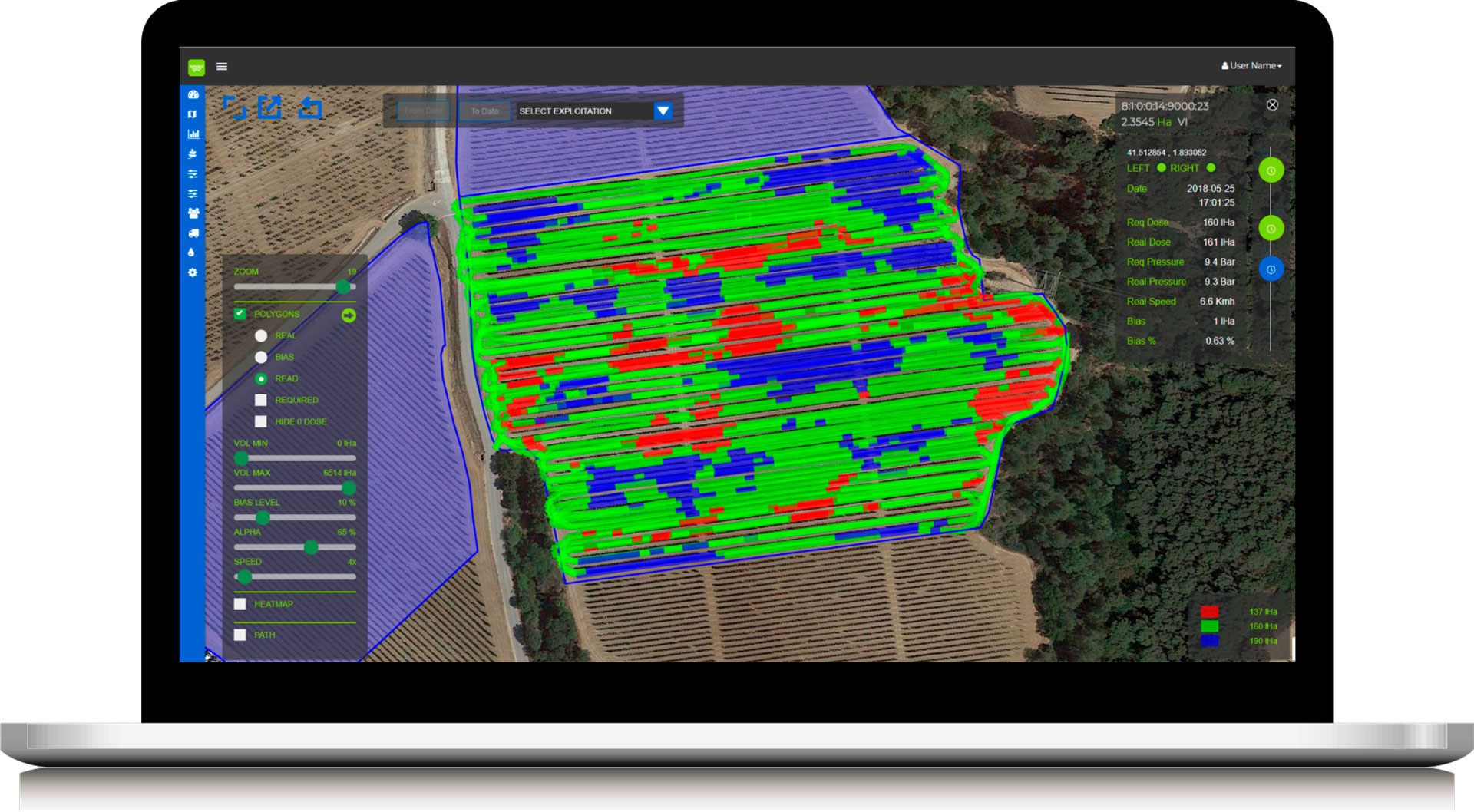

Components of the Waatic kit that is installed on the sprayers to improve crop protection applications.

In 2018, Waatic was established in Spain, and Jupidex imports its smart crop protection applications. Waatic offers smart technology for any air-blast sprayer and is compatible with all Andreoli and CarraroSpray sprayers.

The features of the application include:

- Application settings according to speed or prescription chart

- Flow, pressure, and GPS data are constantly collected and stored for spray programme management

- Sensors control the switching on and off at the ends of rows and between small trees

- Management of operating expenses

- Special mode for large plantations or service companies

“A significant benefit of Waatic kit is that variable application can be done according to a prescribed chart. Which makes it possible to manage and monitor spray programmes from your office, thanks to the main control panel,” Christopher explains.

Christopher adds: ” The university Politencica De Catalunya has done a study regarding the use of the variable rate application and has found up to 20% savings compared to normal use.”

The smart spraying app monitors the flow, pressure, and wind speed automatically. Adaptable application methods ensure that accurate application is done, even when the speed is reduced or increased, which ensures a more consistent product application.

Additional to that, the standard equipment includes sonar sensors, which assist the driver with row-end detection and plant detection. Which means that no products go to waste. The sprayers stop spraying when no plant is detected by the sensors, or whenever moving over from one row to another.

The Waatic system collects data from your orchard or field and stores it in the cloud where it can be analysed and reviewed afterwards.

“All the information collected from the orchard that is being sprayed is gathered on a cloud-based system which is geolocated and mapped and can be analysed and interpreted any time, assisting farmers to make better-informed decisions,” Christopher explains.

More exciting news for farmers is the launch of Pudama and SpotSpray which will be available by 2023.

With SpotSpray you can save costs by using less fertiliser. Thanks to this technique weeds can be

controlled locally, so fewer liquid fertilisers are used.

Optimal crop protection

Kverneland is also taking a step further with the SpotSpray application which is based on prescription cards, meaning that only designated sections are sprayed. With SpotSpray costs can be saved by reducing spraying products used and preserving healthy crops from unnecessary treatment. This also means less crop damage.

More maize with less fertiliser

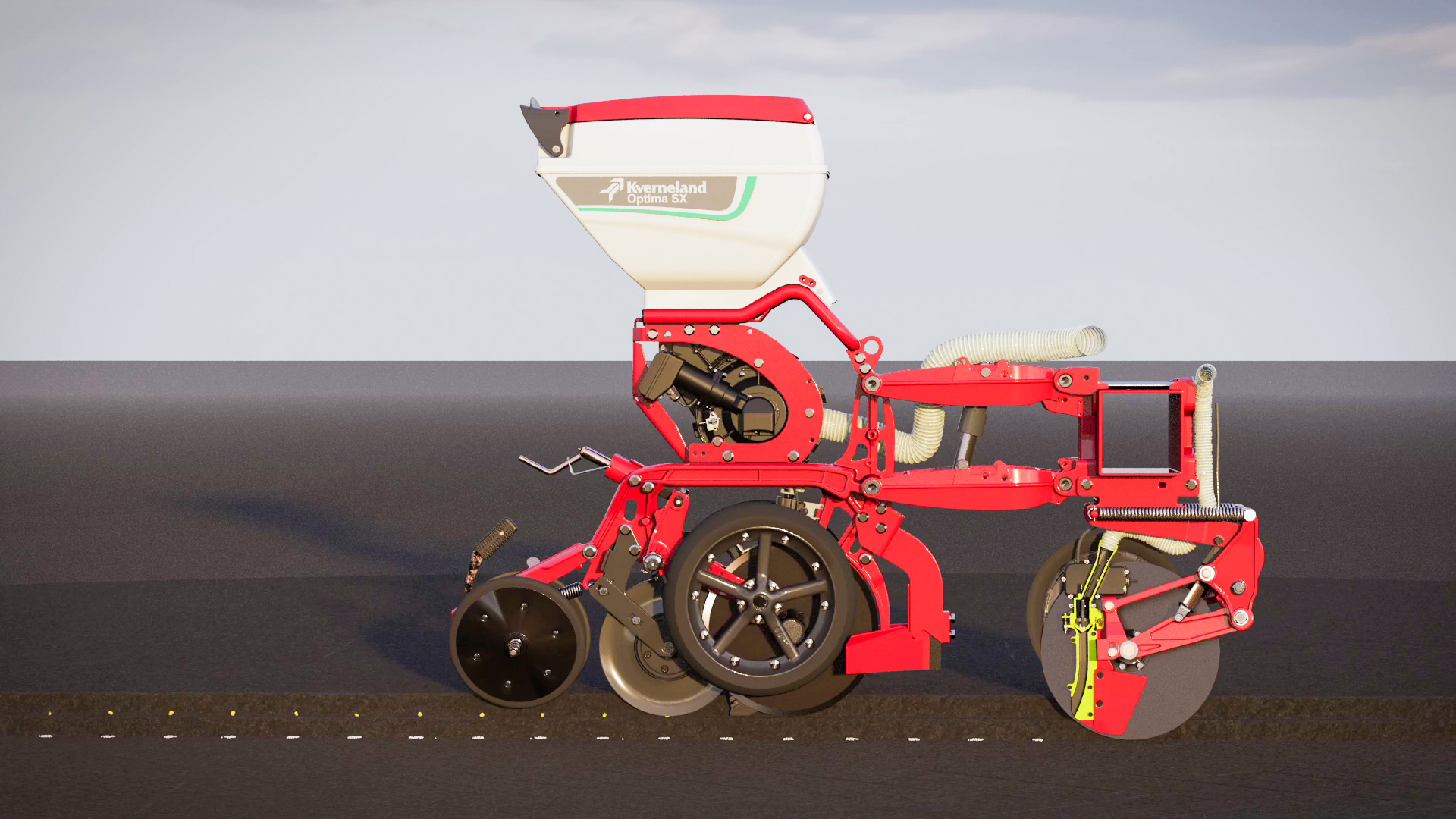

Pudama refers to the method of making precise fertiliser placement underneath maize seeds during planting possible.

Christopher says: “The Pudama composition ensures that seed and fertiliser applications are synchronised via a sensor. Up to 25% less fertiliser can be used without affecting production.”

Pudama makes precision fertiliser placement among maize seeds possible during planting.

The idea behind Pudama was inspired by global maize production with the goal of increasing fertiliser productivity, which in turn promotes the development of young plants and increases fertiliser efficiency (efficient use of fertiliser through reduced leaching) to make fertiliser savings possible.

Christopher elaborates: “The technique results in greater nutrient absorption, because fertiliser is only applied where it is needed, and it prevents excessive nitrate and phosphate from leaching into water systems.”

Christopher explains the process: “The Pudama technique makes the vegetative growth of plants possible, by enabling the roots to grow into the direction of the fertiliser. The aim is to apply fertiliser accurately to each seed. The fertiliser is placed with an air stream that corresponds to the seed distance, 5 centimetres below and to the side of the seed. Pudama is fully compatible with ISOBUS and fully integrates with e-drive II software. A simple click activates the system; no further action is required.”

The Pudama technique enables farmers to apply fertiliser accurately, where needed.

Christopher also highlights the system’s primary advantages; conservation of resources; saving of energy for the production of fertiliser; less leaching (soil) for water protection, but also for other water (sea) due to fewer nutrients for seaweed (algae); less environmental impact (soil, animals, and plants); saving money; time savings in terms of logistics and setting up machines; high-speed plant at up to 15 kph, available on SX row; securing food production; and gaining social acceptance of fertilisers and crop care products (new development).

Conventional band application (left) compared to Pudama (right).

In 2021, Kverneland Group’s Soest GmbH in Germany received the NRW 2021 Efficiency Award for its Pudama precision planter. This machine was awarded since it saves resources and protects the soil against over-fertilisation.

Visit https://ien.kverneland.com/News/Product-news/Archive-Product-News/Archive-2021/SpotSpray-only-spray-when-it-is-needed for more information on Pudama and SpotSpray.

As such, the Jupidex team has been tasked with making farmers aware of the most cutting-edge farming techniques and technology supporting farmers to maximise their outputs while minimising their inputs. Visit https://www.jupidex.co.za/ or call (+27) 33-386 3574 for more information.